Grab, crane grab exactly, is to grab loose bulk material.

Kingda cane grab is organized by two jaws or many jaws assembly together to form a material saving space. During material loading process, the grab is opened and fallen down on material stacks; open-close rope is tension and the grab is closed, at the same time, the supporting rope is pull up, lifting grab to suitable height and transporting to pointed position by upper crane; Thus, release open-close rope, materials are unloaded in wanted areas.

Kingda crane grab, integrated with overhead crane or gantry crane, no need heavy labor, can achieve high loading-unloading efficiency and safety factor, mainly used in ports, power station, steel production plant, yard, chemical factory, scrap yard, ports, mines and railways, water recycling and so on. Different application environment, using different type grab, this this article, we mainly talking about the following crane grab.

1. Four rope crane Grab

Four rope crane grab ( four rope mechanical grab) is used under the integration of gantry crane or overhead crane for grabbing all kinds of loose bulk material, loading, unloading, transportation and material feeding operation.

Different crane grab size to grab different material (density), we usually divide grab working level into light duty, medium duty, heavy duty and super heavy duty, all depending on material’s character and choosing suitable grab.

Four rope crane grab is designed and manufactured by mature technology, every connecting joints’ liner bushing applies quality bearing steel, cutting edge plate is thicken, so the grab is more wear resistant and longer service life.

At the beginning of work, supporting rope lifts the grab to suitable position, then release open-close rope, the grab’s bucket will be forced to open under the acting force of bottom crossbeam’s self-weight, open action will not stop until collision blocks collide, so, the bucket be open to its limited dimension. During bucket’s open activity, the centre distance is increased between upper cross beam pulley and bottom cross beam’s support beam, at this moment, supporting rope falls down to place opening grab to bulk material stockpile. At last, open--close rope is tighten up, center distance between the upper cross beam pulley and bottom cross beam pulley is restored to the original position, thus material grabbing process is finished. The materials have been full filled y in bucket, supporting rope and open-close rope are lift together, whole grab be lift at the same time, and is moved to unloading place by grab crane, then open bucket to unloading all materials.

* Four rope crane grab/bucket technical data sheet:

| No. |

Volume m³ |

working duty |

Density t/m³ |

pulley magnification |

wire rope φmm |

pulley Dia φmm |

grab selfweight

t |

crane capacity

t |

H(closeed) Amm |

H(open) Bmm |

L(closed) Cmm |

L(open) Cmm |

W(open) Emm |

remark |

| 1 |

3 |

light |

≤1 |

3 |

φ16 |

φ400 |

2.75 |

5 |

2922 |

3403 |

2200 |

3020 |

1820 |

|

| 2 |

2.5 |

light |

≤1 |

3 |

φ16 |

φ400 |

2.73 |

5 |

2975 |

3514 |

2200 |

3120 |

1600 |

|

| 3 |

2 |

medium |

> 1~2 |

5 |

φ16 |

φ400 |

2.71 |

5 |

3084 |

3547 |

2150 |

2985 |

1520 |

|

| 4 |

2 |

medium |

> 1~2 |

5 |

φ16 |

φ400 |

2.73 |

5 |

3137 |

3658 |

2150 |

2985 |

1520 |

teeth |

| 5 |

1.5 |

medium |

> 1~2 |

5 |

φ16 |

φ400 |

2.5 |

5 |

2984 |

3429 |

1950 |

2750 |

1360 |

|

| 6 |

1.5 |

medium |

> 1~2 |

5 |

φ16 |

φ400 |

2.57 |

5 |

3037 |

3540 |

1950 |

2860 |

1360 |

teeth |

| 7 |

1 |

heavy |

> 2~2.5 |

6 |

φ16 |

φ400 |

2.45 |

5 |

2855 |

3270 |

1850 |

2535 |

1150 |

|

| 8 |

1 |

heavy |

> 2~2.5 |

6 |

φ16 |

φ400 |

2.5 |

5 |

2908 |

3381 |

1850 |

2635 |

1150 |

teeth |

| 9 |

0.75 |

super heavy |

2.5>~3.3 |

6 |

φ16 |

φ400 |

2.3 |

5 |

2760 |

3144 |

1650 |

2340 |

1054 |

|

| 10 |

0.75 |

super heavy |

2.5>~3.3 |

6 |

φ16 |

φ400 |

2.32 |

5 |

2813 |

3255 |

1650 |

2460 |

1054 |

teeth |

| 11 |

5 |

light |

≤1 |

3 |

φ20 |

φ500 |

4.26 |

10 |

3795 |

4430 |

2820 |

3800 |

2050 |

|

| 12 |

4 |

light |

≤1 |

3 |

φ20 |

φ500 |

4.24 |

10 |

3595 |

4153 |

2445 |

3431 |

2210 |

|

| 13 |

3 |

medium |

> 1~2 |

5 |

φ20 |

φ500 |

4.38 |

10 |

3595 |

4153 |

2445 |

3431 |

1810 |

|

| 14 |

3 |

medium |

> 1~2 |

5 |

φ20 |

φ500 |

4.42 |

10 |

3695 |

4332 |

2445 |

3431 |

1810 |

teeth |

| 15 |

2 |

medium |

> 1~2 |

5 |

φ20 |

φ500 |

4.25 |

10 |

3640 |

4127 |

2200 |

3251 |

1550 |

|

| 16 |

2 |

medium |

> 1~2 |

5 |

φ20 |

φ500 |

4.29 |

10 |

3694 |

4268 |

2200 |

3251 |

1550 |

teeth |

| 17 |

2 |

heavy |

> 2~2.5 |

6 |

φ20 |

φ500 |

3.95 |

10 |

3640 |

4127 |

2200 |

3251 |

1550 |

|

| 18 |

2 |

heavy |

> 2~2.5 |

6 |

φ20 |

φ500 |

4 |

10 |

3694 |

4268 |

2200 |

3251 |

1550 |

teeth |

| 19 |

1.5 |

super heavy |

2.5>~3.3 |

6 |

φ20 |

φ500 |

3.78 |

10 |

3357 |

3814 |

2020 |

2969 |

1470 |

|

| 20 |

1.5 |

super heavy |

2.5>~3.3 |

6 |

φ20 |

φ500 |

3.82 |

10 |

3409 |

3955 |

2020 |

2969 |

1470 |

teeth |

| 21 |

1 |

heavysuper |

2.5>~3.3 |

6 |

φ20 |

φ500 |

3.46 |

10 |

3052 |

3445 |

1676 |

2280 |

1464 |

|

| 22 |

1 |

heavysuper |

2.5>~3.3 |

6 |

φ20 |

φ500 |

3.5 |

10 |

3141 |

3578 |

1676 |

2280 |

1464 |

teeth |

| 23 |

8 |

light |

≤1 |

3 |

φ24 |

φ600 |

7.96 |

16 |

4545 |

5292 |

3205 |

4387 |

2370 |

|

| 24 |

7 |

light |

≤1 |

3 |

φ24 |

φ600 |

7.54 |

16 |

4610 |

5359 |

3166 |

4530 |

2297 |

|

| 25 |

6 |

light |

≤1 |

3 |

φ24 |

φ600 |

7.6 |

16 |

4610 |

5359 |

3166 |

4530 |

2000 |

|

| 26 |

6 |

light |

≤1 |

3 |

φ24 |

φ600 |

7.69 |

16 |

4700 |

5490 |

3166 |

4530 |

2000 |

teeth |

| 27 |

6 |

medium |

> 1~2 |

5 |

φ24 |

φ600 |

7.77 |

16 |

4610 |

5359 |

3166 |

4530 |

2000 |

|

| 28 |

6 |

medium |

> 1~2 |

5 |

φ24 |

φ600 |

7.86 |

16 |

4700 |

5490 |

3166 |

4530 |

2000 |

teeth |

| 29 |

4.8 |

medium |

> 1~2 |

5 |

φ24 |

φ600 |

7.66 |

16 |

4320 |

4948 |

2820 |

4068 |

2020 |

|

| 30 |

4.8 |

medium |

> 1~2 |

5 |

φ24 |

φ600 |

7.82 |

16 |

4410 |

5080 |

2820 |

4068 |

2020 |

teeth |

| 31 |

4 |

heavy |

> 2~2.5 |

5 |

φ24 |

φ600 |

7.36 |

16 |

4320 |

4948 |

2820 |

4068 |

1770 |

|

| 32 |

4 |

heavy |

> 2~2.5 |

5 |

φ24 |

φ600 |

7.52 |

16 |

4410 |

5080 |

2820 |

4068 |

1770 |

teeth |

| 33 |

3.2 |

heavy |

> 2~2.5 |

6 |

φ24 |

φ600 |

7.65 |

16 |

4175 |

4750 |

2600 |

3726 |

1781 |

|

| 34 |

3.2 |

heavy |

> 2~2.5 |

6 |

φ24 |

φ600 |

7.75 |

16 |

4265 |

4880 |

2600 |

3726 |

1781 |

teeth |

| 35 |

2.5 |

super heavy |

2.5>~3.3 |

6 |

φ24 |

φ600 |

6.88 |

16 |

4117 |

4642 |

2350 |

3431 |

1550 |

|

| 36 |

2.5 |

super heavy |

2.5>~3.3 |

6 |

φ24 |

φ600 |

6.98 |

16 |

4210 |

4772 |

2350 |

3431 |

1550 |

teeth |

| 37 |

10 |

light |

≤1 |

3 |

φ28 |

φ700 |

10.52 |

20 |

5103 |

5850 |

3500 |

5021 |

2496 |

|

| 38 |

10 |

light |

≤1 |

3 |

φ28 |

φ700 |

10.66 |

20 |

5202 |

6029 |

3500 |

5021 |

2496 |

teeth |

| 39 |

8 |

light |

≤1 |

5 |

φ28 |

φ700 |

10.72 |

20 |

5103 |

5850 |

3500 |

5021 |

2096 |

|

| 40 |

8 |

light |

≤1 |

5 |

φ28 |

φ700 |

10.86 |

20 |

5202 |

6029 |

3500 |

5021 |

2096 |

teeth |

| 41 |

6 |

medium |

> 1~2 |

5 |

φ28 |

φ700 |

10 |

20 |

4172 |

5455 |

3200 |

4557 |

2220 |

|

| 42 |

6 |

medium |

> 1~2 |

5 |

φ28 |

φ700 |

10.2 |

20 |

4271 |

5634 |

3200 |

4557 |

2220 |

teeth |

| 43 |

4 |

heavy |

> 2~2.5 |

6 |

φ28 |

φ700 |

9.8 |

20 |

4583 |

5250 |

2900 |

4124 |

1890 |

|

| 44 |

4 |

heavy |

> 2~2.5 |

6 |

φ28 |

φ700 |

10 |

20 |

4682 |

5430 |

2900 |

4150 |

1890 |

teeth |

| 45 |

3 |

super heavy |

2.5>~3.3 |

6 |

φ28 |

φ700 |

8.85 |

20 |

4431 |

4903 |

2399 |

3822 |

1890 |

|

| 46 |

3 |

super heavy |

2.5>~3.3 |

6 |

φ28 |

φ700 |

9.05 |

20 |

4530 |

5083 |

2399 |

3822 |

1890 |

teeth |

2. Two Rope Crane Grab

two rope crane grab is used under the integration of overhead crane, port crane, and electric winch, widely used in port,

power station, yard, chemical factory, to grab all kinds of ore, coal, slag and so on, for loading, unloading, transportation and charging material.

On the winch, there are two ropes, one for supporting the whole grab in the air, the other for grab’s open and close. When the grab is fall down on the material, open-close rope is tightened up to catch and close loose material, at the same time, supporting rope is lift too, the grab is lift and transported to pointed position; then release open-close rope, grab is opened and loose material falls on right place.

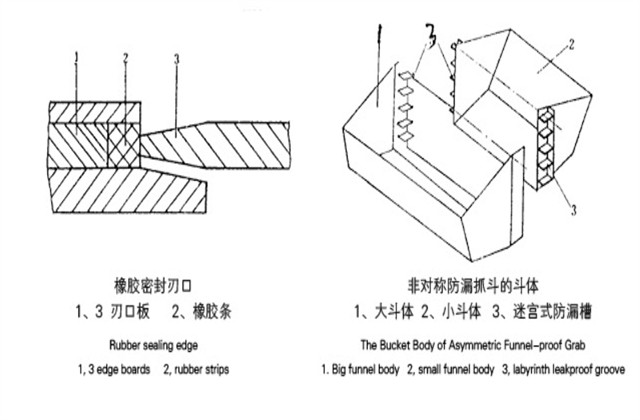

3. Anti Leakage Crane Grab

In the processing of grabbing bulk material, some special material has good fluidity and with small internal adhesion and friction, easily side leakage from grab’s gap, for example: fertilizer, alumina and so on. Material leakage’s main parts is at the bucket’s horizontal cutting edge, so, need to design special anti-leakage crane grab.

At the beginning of work, supporting rope lifts the grab to suitable position, then release open-close rope, the grab’s bucket will be forced to open under the acting force of bottom crossbeam’s self-weight, until collision blocks collide, open will be stopped, so, the bucket be open to its limit dimension. At the bucket open activity, the centre to centre spacing is increased between upper cross beam pulley and bottom cross beam’s support beam, then supporting rope fall down to place opening grab to grabbing bulk material stockpile. At final, the open--close rope be tighten up, center distance between the upper cross beam pulley and bottom cross beam pulley is restored to the original position, thus material grabbing process is finished. The materials have been full filled in bucket, supporting rope and open-close rope are lift together, whole grab be lift at the same time, and is moved to unloading place by grab crane, then open bucket to unloading all materials.

Remark: anti leakage crane grab’s pulley magnification should not less than 5, and grab body’s stiffness-processing and assembly-accuracy all need high requirements.

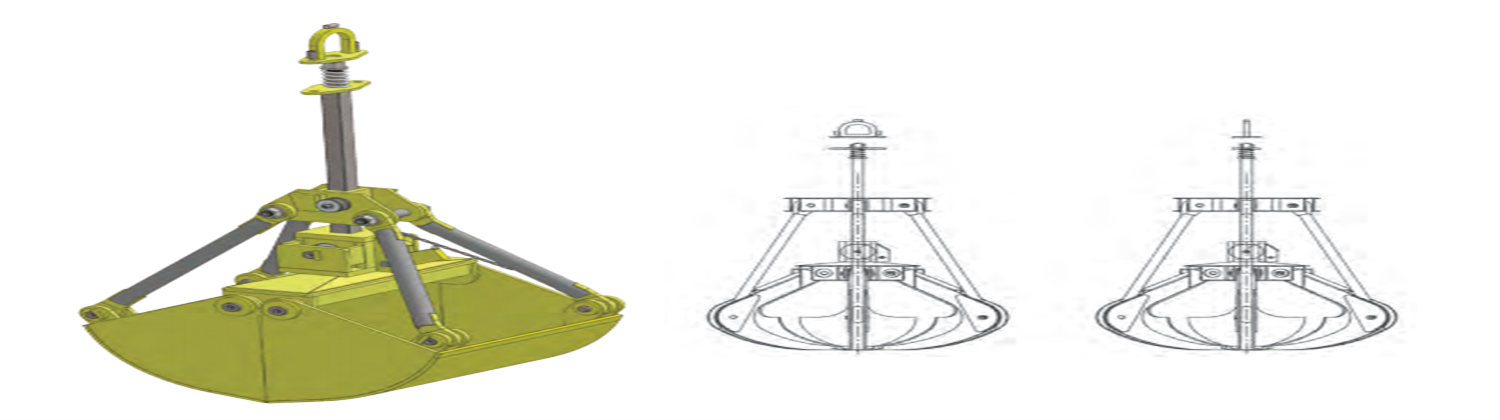

4. Multi-Jaw Crane Grab / Orange Peel Crane Grab

For multi-jaw crane grab/bucket, there are 4 jaw grabs, 6 jaw grab and 8 jaw grabs. There are also single rope multi-jaw grab, double rope multi-jaw grab, four rope multi-jaw grab, hydraulic multi-jaw grab and motor multi-jaw grab, five types.

Multi-petal crane grab mainly used for grabbing materials which in harsh environment, irregular and hard to grab, for example: waste, ore, scrap steel, aluminum ingot, limestone, gravel and other material for loading, unloading and shipment, this type grab wildly used in garbage dump, scrap yard, ports, mines and railways. (Motor grab cannot be used under water)

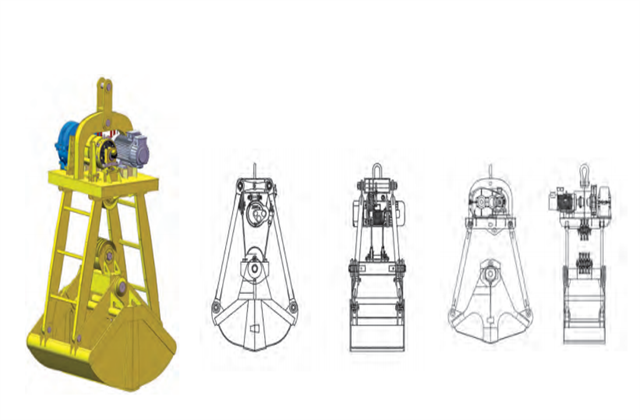

5. Electric Crane Grab

Electric crane grab is mainly used to load and unload loose materials: ore, limestone, slag, pulverized coal, coke and so on, cannot launching operation.

Grab’s lifting-lowering motion depends on a single drum lifting mechanism or hanging on hook, open-close motion depends on the components fitted on grab’s head: motor, gear box, drum which can drive bottom cross beam to finish open-close operation.

When the grab works in outdoor, rain-proof devices should be applied, cannot be use in inflammable, explosive, acid and alkali vapor environments.

6. Motor Crane Grab

Motor crane grab be used for grabbing granular materials, such as ore, sand carbide, slag, ore power, coke, coal, loose clay, etc. Also, like electric grab, motor grab cannot be used underwater.

Motor crane grab’s lifting motion depends on a single drum lifting mechanism or hanging on hook, the grab is fitted with open-close mechanism itself in many types. Kingda crane motor grab’s open-close motion depends on electric hoist to finish which is installed inner the grab. Don’t like Four rope crane grab, there no upward pulling force when the grab is opened or closed, grab’s deadweight all be used for grabbing, so grabbing force is great, suitable for grasping material which is hard to grasp, such as ores.

7. Electric Hydraulic Crane Grab

Electric hydraulic crane grab is divided into multi petals electric hydraulic grab and double petals electric hydraulic grab.

Electric hydraulic orange peel crane grab mainly is used for loading and unloading irregular bulk cargo, such as scrap steel, pig iron, stone, etc. It is suitable for steel works , waste incineration treatment, ports, railways transit and other occasions.

Electric hydraulic double jaw crane grab can be used for loading and unloading irregular bulk cargo of all kinds of crane, maximum particle size should be less than 100 mm, especially on container crane, marine crane and multi-functional crane, which can greatly improve crane’s comprehensive performance.

Not matter for multi jaw or double jaw crane grab, the grab is fitted with electric hydraulic system itself to complete its open-close action, comprehensively apply for electrical hydraulic technology, mechanical technology, system design, high level automation, high efficiency and energy saving, with higher excavating and closing ability than same specification’s rope grab.

* multi-jaw electric hydraulic grab technical data sheet:

| No. |

Volume

m³ |

working duty |

Density

t/m³ |

power

kw |

grab selfweight t |

crane capacity t |

H(closeed) Amm |

L(closed)

Cmm |

H(open)

Bmm |

L(open)

Cmm |

jaw Number |

remark |

| 1 |

2 |

heavy |

2.5 |

22 |

4.5 |

|

|

|

|

|

|

|

| 2 |

5 |

medium |

1.35 |

37 |

3.6 |

10 |

3381 |

2760 |

2820 |

3930 |

6 |

complete closed |

| 3 |

5 |

light |

0.5 |

18.5 |

3.1 |

10 |

3381 |

2760 |

2820 |

3930 |

6 |

complete closed |

| 4 |

8 |

light |

1 |

30 |

5.1 |

16 |

3749 |

3166 |

3000 |

5000 |

6 |

semi-closed |

| 5 |

4 |

light |

1 |

18.5 |

4 |

10 |

3100 |

2635 |

2545 |

4025 |

6 |

semi-closed |

| 6 |

6.3 |

light |

1 |

30 |

5.9 |

16 |

4520 |

3090 |

3880 |

4860 |

6 |

semi-closed |

| 7 |

10 |

light |

1 |

45 |

7.48 |

20 |

4530 |

3280 |

3650 |

5150 |

6 |

semi-closed |

| 8 |

12 |

light |

1 |

45 |

7.6 |

20 |

3988 |

3717 |

3262 |

5489 |

6 |

semi-closed |

| 9 |

8 |

light |

1 |

30 |

5.2 |

16 |

3789 |

3167 |

3025 |

4965 |

6 |

semi-closed |

| 10 |

8 |

medium |

1.5 |

37 |

8.5 |

20 |

3560 |

3365 |

2790 |

5080 |

6 |

complete closed |

| 11 |

1.5 |

heavy |

1.5 |

22 |

3.78 |

8 |

2937 |

2040 |

2668 |

3350 |

6 |

complete closed |

| 12 |

1.5 |

medium |

0.8~1.4 |

15 |

2.5 |

5 |

3326 |

1896×1600 |

3279 |

2230×1600 |

2 |

teeth |

| 13 |

4 |

medium |

1.1~1.3 |

18.5 |

3.4 |

10 |

3100 |

2200×2100 |

3910 |

2930×2100 |

2 |

|

| 14 |

3 |

heavy |

1.7~2.5 |

22 |

3.5 |

12 |

2957 |

2035×1826 |

2763 |

2582×1826 |

2 |

|

| 15 |

2.5 |

heavy |

1.7~2.5 |

22 |

3.5 |

12 |

2997 |

2035×1826 |

2803 |

2582×1826 |

2 |

|

| 16 |

2.5 |

medium |

1.0~1.3 |

15 |

3.11 |

10 |

3123 |

2023×1822 |

2953 |

2652×1822 |

2 |

teeth |

| 17 |

5 |

medium |

1.0~1.3 |

22 |

4.7 |

16 |

3560 |

3420×2400 |

3230 |

3050×2400 |

2 |

teeth |

| 18 |

3.2 |

medium |

1.0~1.3 |

15 |

3.4 |

10 |

3059 |

2668×2000 |

3101 |

2945×2000 |

2 |

|

8. Electric Single Monorail for Rope Crane Grab

Electric single monorail for rope grab is an overhead lifting and transporting equipment, don’t occupying many production areas, completely relay on overhead monorail to finish material’s transportation, and carry out open-close and lifting at the same time.

This grab can b operate easily, with reliable performance and high efficiency, is widely used in ports, buildings, construction sites, workshops, coal yards, warehouses, slag pools, etc. The grab can be operated on the ground by pendant, in the air with cab, and also can be operated by wireless radio (work principle same as Four rope crane grab).

9. Single Rope Suspended Crane Grab

Single rope suspended crane grab is divided into single rod and double rods, its usage and operation are the same, but this type grab cannot be open in the air.

Suspended crane grab is used when there is lifting drum only (single hook) in any kinds of general crane, suitable for grabbing various loose materials, and most suitable for grabbing under the water.

| No. |

Volume

m³ |

working

duty |

Density

t/m³ |

pulley magnification |

wire

rope

φmm |

pulley

Dia

φmm |

grab

selfweight

t |

crane

capacity

t |

H

(closeed)

A mm |

| 1 |

0.3 |

light |

1.2 |

2 |

φ13 |

φ200 |

0.8 |

2 |

2960 |

| 2 |

0.5 |

light |

1.2 |

2 |

φ15 |

φ200 |

1.1 |

3 |

2960 |

| 3 |

0.75 |

heavy |

2.2 |

2 |

φ13 |

φ240 |

1.8 |

5 |

2785 |

| 4 |

0.75 |

super heavy |

2.6 |

2 |

φ13 |

φ240 |

2.05 |

5 |

2785 |

| 5 |

1 |

heavy |

2.4 |

2 |

φ16 |

φ240 |

1.8 |

5 |

2789 |

| 6 |

1 |

light |

1.2 |

2 |

φ16 |

φ190 |

1.6 |

5 |

2779 |

| 7 |

1.5 |

heavy |

2 |

2 |

φ16 |

φ300 |

2.4 |

5 |

3401 |

| 8 |

1.5 |

super heavy |

2.8 |

2 |

φ18 |

φ300 |

3 |

10 |

3426 |

10. Stainless Steel Crane Grab

Stainless steel crane grab is customized specially for brewing in winery or food factory, used for grabbing and transporting koji sauce, sauce residue and so on.

For workshop and processed food, stainless steel grab is clean processing by using stainless steel crane grab, and greatly reduces labor number.

Stainless steel crane grab also can be divided into four ropes stainless steel grab, double ropes stainless steel grab, single ropes stainless steel grab and electric stainless steel grab. It is the same as other structure grab, different feature is: stainless steel grab’s processing material must be stainless steel, but, the same working principle.

11. Loose material specific gravity/density

| Material |

specific gravity(t/m³) |

Material |

specific gravity(t/m³) |

| anthracite |

0.7~1.0 |

pyrite(block) |

2~2.6 |

| bituminous coal |

0.8 |

manganese ore |

1.7~1.9 |

| lignite |

0.6~0.8 |

magnesia(block) |

2.2~2.5 |

| peat |

0.29~0.5 |

powery magnesia |

2.1~2.2 |

| peat(wet) |

0.55~0.65 |

copper mine |

1.7~2.1 |

| coke |

0.36~0.63 |

copper concentrate |

1.3~1.8 |

| charcial |

0.2~0.4 |

lead concentrate |

1.9~2.4 |

| anthracite dust |

0.84~0.89 |

zinc concentrate |

1.3~1.7 |

| bituminous coal fines |

0.4~0.7 |

lead-zinc concentrate |

1.3~2.4 |

| plumbago |

0.45 |

ore sintering caking |

1.7~2.0 |

| magnetite |

2.5~3.5 |

bump sintering caking |

1.4~1.6 |

| hematite |

2.0~2.8 |

lead singtering caking |

1.8~2.2 |

| limonite |

1.2~2.1 |

lead-zinc sintering caking |

1.6~2.0 |

| zinc dust |

0.7~1.5 |

big limestone block |

1.6~2.0 |

| pyrite cinder |

1.7~1.8 |

mediu limestone block |

1.2~1.5 |

| lead-zinc briquette |

1.3~1.8 |

small limestone block |

1.2~1.5 |

| pyrite pellet |

1.2~1.4 |

quicklime |

1.7~1.8 |

| open-hearth slag(coarse) |

1.6~1.85 |

rubble |

1.32~2.0 |

| blast furnace slag |

0.6~1.0 |

dolomite(block) |

1.2~2.0 |

| lead-zinc liquid disintegrating slag |

1.5~1.6 |

small piece dolomite |

1.8~1.9 |

| dry coal ash |

0.64~0.72 |

gravel |

1.5~1.9 |

| coal ash |

0.7 |

gravel(small block) |

0.7~1.5 |

| coarse sand(dry) |

1.4~1.9 |

gravel(wet) |

1.7 |

| coarse sand(wet) |

1.4~1.65 |

cement |

0.9~1.7 |

| fine sand(wet) |

1.8~2.1 |

hydrated lime(power) |

0.5 |

| moulding sand |

0.8~1.3 |

hydrated lime |

2 |

| Material type |

Grabbing material |

Material density(t/m³) |

| light |

coke,slag, cereal, potato, cement, soil and gravel, clay, brickbat, lime, mid-size anthracite |

0.5~1.2 |

| medium |

peat, big-size anthracite, compacted coal, clay, limestone, breakstone, salt, gravel, fragment of brick, bauxite, tablet iron oxide skin, cement, brick and sand in water,etc. |

> 1.2~2.0 |

| heavy |

limestone, heavy clay, mediu-small size mineral, lead-zinc minral, hard stones, stick column iron oxide iron ore |

> 2.0~2.6 |

| super heavy |

big size ore, big size manganese ore, seated and clumped lead-zinc power |

> 2.6~3.3 |

.png)

.png)