1. Crane General Introduction

Kingda crane Low headroom single girder overhead traveling crane (in other words: single girder EOT crane) is modular designed theories lifting equipment.

By modern computer technology, technical department introduces optimized and reliable design methods, applying for new-advanced crane component, new material and new technology, to get a light weight, universal, energy-saving, maintenance-free and environment-friendly single girder EOT crane.

Design, manufacturing and inspection all process applies the latest China and international standard, for example: FEM, DIN ,IEC. Compared with traditional single girder overhead traveling crane, low headroom single girder EOT crane ‘s deadweight is reduced up to 15-30%, the max wheel pressure is reduced 10-35% more or less, so the factory owner can reduce its investment on workshop structure, thanks to crane’s light self-weight and small wheel pressure on the steel structure.

In Kingda crane's workshop, low headroom Single girder overhead traveling crane(low headroom single girder EOT crane)’s core driving component: gearbox completely adopts harden tooth with high accuracy gear pair, and fitted with steel drum, forged wheel and frequency inverter speed control system, this crane to be the best replacement for traditional single girder EOT crane,mainly used in General mechanical engineering, assembling, petrochemicals, warehouse logistics, power station, paper making and light working workshop, you also can call it "workshop single girder overhead traveling crane"

2. Low Headroom Single Girder Overhead Travelling Crane Features:

1. Lifting mechanism: headroom electric hoist wire rope hoist

2. For all driving mechanism: lifting, cross travel and long travel, adopt European 3 in 1 technology, harden tooth surface gear box, impact structure, small noise, no oil leak and long service life.

3. Introduce high strength material, all crane’s geometry dimension is reduced, light deadweight. In the same workshop height, Headroom Single girder overhead traveling crane (single girder EOT crane) can fulfil higher lifting height than traditional single girder EOT crane.

4. Modular design, short design period, high generalization, improve utilization of the component

5. Compact structure, headroom, big hook approach, high efficiency

6. All speed controlled by inverter, smooth run, no impact, fast speed in light lifting, low speed in heavy lifting. energy saving. Sometimes, we call it frequency inverter speed controlled single girder EOT crane

7. Low cost on operation and maintenance

8. High performance

9. Easy to operate

- 1) Remote operation

- 2) Cable Pendant

- 3) Cabin

10. Safety and reliable

- 1) Linkage

- 2) Overload protection

- 3) Zero protection

- 4) Travel limit switch

- 5) Steel reel with small deflection, small wear

- 6) Motor protection class: IP55 ;

- 7) Insulation class: F

- 8) Motor fitted with air-cooling system, thermal protection function

- 9) Fast and easy positioning

- 10) PLC+man-machine interface(option)

- 11) Safety monitoring system(option)

| Drum assembling |

Hoist steel structure assembling |

Motor |

Wire rope |

| Material: Q355, round steel |

Material: Q235 |

ABM/ SEW/China top brand |

galvanizing, high strength, steel/fiber core |

|

|

|

|

| Hook block |

Lifting limit switch |

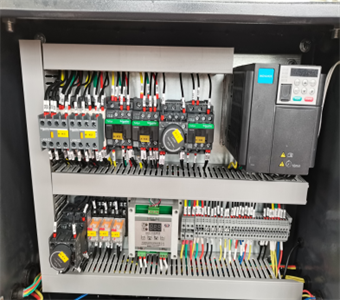

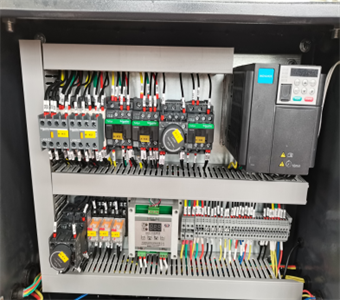

control box |

Main girder assembling |

| forged, hook: DG34CrMo, pulley: Nylon; safety latch |

cam rotating type |

Main electrical component: ABB/Schneider |

robot welding for main girder inner welding seam |

|

|

|

|

| Electric hoist loading test |

|

|

|

|

| inspection |

| Ultrasonic Detection |

Ultrasonic Detection |

Magnetic Particle Detection |

Painting Test |

|

|

|

|

| Main girder painting |

End girder assembling |

packing and shipping |

| zinc rich epoxy primer, Polyurethane Topcoat |

SEW 3 IN I long travel motor |

|

|

|

|

4. Low Headroom Single Girder Overhead Travelling Crane Technical Parameter:

lifting capacity

(t) |

span

(m) |

lifting height

(m) |

working class |

lifting speed (m/min) |

weight(kg) |

recommend

rail |

power (kw) |

Max. wheel

(Kn) |

| hoist |

whole crane |

| 1 |

9.5 |

3/6/9/12 |

A5(2m) |

0.8/5 |

376 |

958 |

P24 |

4.58 |

8.76 |

| 11 |

1599 |

9.51 |

| 12.5 |

1723 |

10.45 |

| 16 |

2220 |

11.58 |

| 19.5 |

2835 |

13.06 |

| 22.5 |

3532 |

14.62 |

| 24 |

3774 |

16.1 |

| 2 |

9.5 |

3/6/9/12 |

A5(2m) |

0.8/5 |

376 |

1625 |

P24 |

4.58 |

13.5 |

| 11 |

1784 |

14.46 |

| 12.5 |

1970 |

15.54 |

| 16 |

2371 |

17.47 |

| 19.5 |

3175 |

18.93 |

| 22.5 |

3726 |

20.39 |

| 24 |

4016 |

22.38 |

| 3 |

9.5 |

3/6/9/12 |

A5(2m) |

0.8/5 |

376 |

1802 |

P24 |

4.58 |

18.96 |

| 11 |

2168 |

20.11 |

| 12.5 |

2350 |

21.85 |

| 16 |

2872 |

23.51 |

| 19.5 |

3854 |

4.49 |

25.45 |

| 22.5 |

4549 |

27.06 |

| 24 |

4855 |

30.6 |

| 5 |

9.5 |

3/6/9/12 |

A5(2m) |

0.8/5 |

531 |

2318 |

P24 |

7.84 |

28.2 |

| 11 |

2566 |

29.76 |

| 12.5 |

2816 |

31.8 |

| 16 |

3673 |

33.84 |

| 19.5 |

4364 |

8.24 |

35.62 |

| 22.5 |

5392 |

39.78 |

| 24 |

5754 |

42.62 |

| 10 |

9.5 |

3/6/9/12 |

A5(2m) |

0.8/5 |

928 |

3260 |

P38 |

12.66 |

51.85 |

| 11 |

3596 |

44.44 |

| 12.5 |

3896 |

57.7 |

| 16 |

4889 |

60.83 |

| 19.5 |

5913 |

64 |

| 22.5 |

7527 |

67.26 |

| 24 |

7975 |

71.36 |

| 16 |

9.5 |

3/6/9/12 |

A5(2m) |

0.66/4 |

1420 |

4284 |

P43 |

19.48 |

83.1 |

| 11 |

4846 |

86.1 |

| 12.5 |

5336 |

88.5 |

| 16 |

6305 |

93 |

| 19.5 |

8111 |

20.28 |

98.4 |

| 22.5 |

9416 |

102.3 |

| 24 |

10065 |

104.2 |

| 20 |

9.5 |

3/6/9/12 |

A5(2m) |

0.66/4 |

1420 |

4944 |

P43 |

19.48 |

101.1 |

| 11 |

5441 |

105.3 |

| 12.5 |

5906 |

107.1 |

| 16 |

6756 |

111.6 |

| 19.5 |

8307 |

20.28 |

117.1 |

| 22.5 |

8500 |

118 |