1. Overhead Traveling Crane Introduction

Overhead traveling crane is a lifting equipment that is horizontally mounted over workshops, warehouses, and material yards for material lifting. Due to its two ends located on tall cement columns or metal supports, resembling a bridge, it is called an overhead traveling crane.

The bridge of the overhead traveling crane runs longitudinally along the rails laid on both sides of the elevated structure, making full use of the space under the bridge to lift materials without being obstructed by ground equipment. It is the most widely used and numerous type of lifting machinery.

Kingda crane has served industrial community by providing high-quality crane and service with more than 4,500 employees, 1.62 million M3 workshop and 3500 sets intelligent manufacturing facility. Our product covers electric hoist, overhead crane, gantry crane, grab crane, casting/ladle crane, electromagnet crane, anti-explosion crane, cleaning room crane and their spare parts.

Here, we will have a detailed introduction to the kinds of Kingda overhead traveling crane.

2. Overhead Traveling Crane Classification

2.1 Single girder overhead crane

2.1.1 Headroom single girder overhead traveling crane

This crane is a new type of crane that our company has introduced and digested advanced foreign technology, guided by modular design theory and modern computer technology. Kingda headroom single girder overhead traveling crane introduces optimization design and reliability design methods. It is completed with imported configurations, new materials, and new processes, and is lightweight, universal, energy-saving, environmentally friendly, maintenance free, and high-tech.

The main beam and end beam are box weld structure, hoist runs on the lower flange. Main beam and end beam are connected by high-strength bolts for easy transportation and on-site installation. The lifting mechanism adopts a new type of electric hoist, which has a compact structure and is easy to maintain.

Technical Parameter

| lifting capacity |

span |

lifting height |

working class |

lifting speed (m/min) |

weight(kg) |

recommend |

power (kw) |

Max. wheel |

| (t) |

(m) |

(m) |

hoist |

whole crane |

rail |

(Kn) |

| 1 |

9.5 |

3/6/9/12 |

A5(2m) |

0.8/5 |

376 |

958 |

P24 |

4.58 |

8.76 |

| 11 |

1599 |

9.51 |

| 12.5 |

1723 |

10.45 |

| 16 |

2220 |

11.58 |

| 19.5 |

2835 |

13.06 |

| 22.5 |

3532 |

14.62 |

| 24 |

3774 |

16.1 |

| 2 |

9.5 |

3/6/9/12 |

A5(2m) |

0.8/5 |

376 |

1625 |

P24 |

4.58 |

13.5 |

| 11 |

1784 |

14.46 |

| 12.5 |

1970 |

15.54 |

| 16 |

2371 |

17.47 |

| 19.5 |

3175 |

18.93 |

| 22.5 |

3726 |

20.39 |

| 24 |

4016 |

22.38 |

| 3 |

9.5 |

3/6/9/12 |

A5(2m) |

0.8/5 |

376 |

1802 |

P24 |

4.58 |

18.96 |

| 11 |

2168 |

20.11 |

| 12.5 |

2350 |

21.85 |

| 16 |

2872 |

23.51 |

| 19.5 |

3854 |

4.49 |

25.45 |

| 22.5 |

4549 |

27.06 |

| 24 |

4855 |

30.6 |

| 5 |

9.5 |

3/6/9/12 |

A5(2m) |

0.8/5 |

531 |

2318 |

P24 |

7.84 |

28.2 |

| 11 |

2566 |

29.76 |

| 12.5 |

2816 |

31.8 |

| 16 |

3673 |

33.84 |

| 19.5 |

4364 |

8.24 |

35.62 |

| 22.5 |

5392 |

39.78 |

| 24 |

5754 |

42.62 |

| 10 |

9.5 |

3/6/9/12 |

A5(2m) |

0.8/5 |

928 |

3260 |

P38 |

12.66 |

51.85 |

| 11 |

3596 |

44.44 |

| 12.5 |

3896 |

57.7 |

| 16 |

4889 |

60.83 |

| 19.5 |

5913 |

64 |

| 22.5 |

7527 |

67.26 |

| 24 |

7975 |

71.36 |

| 16 |

9.5 |

3/6/9/12 |

A5(2m) |

0.66/4 |

1420 |

4284 |

P43 |

19.48 |

83.1 |

| 11 |

4846 |

86.1 |

| 12.5 |

5336 |

88.5 |

| 16 |

6305 |

93 |

| 19.5 |

8111 |

20.28 |

98.4 |

| 22.5 |

9416 |

102.3 |

| 24 |

10065 |

104.2 |

| 20 |

9.5 |

3/6/9/12 |

A5(2m) |

0.66/4 |

1420 |

4944 |

P43 |

19.48 |

101.1 |

| 11 |

5441 |

105.3 |

| 12.5 |

5906 |

107.1 |

| 16 |

6756 |

111.6 |

| 19.5 |

8307 |

20.28 |

117.1 |

| 22.5 |

8500 |

118 |

2.1.2 China Type Single Girder Overhead Traveling Crane

China type single girder overhead traveling crane compose of by main girder welded by I beam and steel plate, end girder electric hoist and traveling mechanism. The electric hoist runs along the bottom flange of the main girder to complete the material lifting. The crane has the characteristics of lightweight in structure and easy yo install and maintain, widely used in lifting goods in different occasions such as factories, warehouses, and material yards. It is prohibited to use it in flammable, explosive, and corrosive media environments. The working level is A3-A5. There are three operating modes: cable pendant in ground, wireless remote control, and driver's cab. There are two types of cabins: open and closed. The operation of the crane adopts a separate drive form. Crane bridge travels in a separate drive, conical motor brakes and open gear transmit.

| Technical Parameter |

| Lifting Capacity(T) |

1-5 |

10 |

16 |

20 |

| Span(m) |

7.5-30 |

7.5-30 |

7.5-30 |

7.5-20 |

| Crane travel Mechanism |

travel speed(m/min) |

20 (Gound) |

30 (Cab) |

20 Ground) |

30 (Cab) |

20 Ground) |

20 Ground) |

| speed ratio |

58.78 |

39.38 |

58.78 |

39.38 |

58.78 |

58.78 |

| motor |

power(kw) |

2*0.8/4*0.8 |

2*1.5 |

2*1.5/4*0.8 |

2*1.5 |

2*1.5/4*1.5 |

4*1.5 |

| rotation speed(n/min) |

1380 |

7.5-22.5/22.5-31.5 |

7.5-22.5 |

7.5-14/14-19.5 |

7.5-31.5 |

| Electric Hoist |

Electric hoist |

single speed |

double speed |

single speed |

double speed |

single/double speed |

single/double speed |

| Lifting speed(m/min) |

8 |

8/0.8 |

7 |

7/0.7 |

3.5 |

3.5 |

| Cross speed(m/min) |

20 |

20 |

20 |

20 |

| Motor |

cone squirrel-cage model |

cone squirrel-cage model |

cone squirrel-cage model |

cone squirrel-cage model |

| working class |

A3 A4 A5 |

A3 A4 A5 |

A3 A4 A5 |

A3 A4 A5 |

| Power voltage |

380V-690V |

380V-690V |

380V-690V |

380V-690V |

| wheel diameter(mm) |

Φ270 |

Φ270 |

Φ270 |

Φ270 |

| Rail width |

37-70mm |

37-70mm |

51-70mm |

51-70mm |

2.2 Single Girder Suspension Overhead Traveling Crane

Single girder overhead traveling crane consists of main girder welded by steel plate and I-beam, end girder, electric hoist and electric trolley. The crane is hung on I-beam on the upper of the workshop, cantilever is from 0.5~1m, the electric hoist runs along the bottom flange of the main girder I-beam to complete the lifting work. The single girder suspension crane features with lightweight in structure, easy to install and maintain, widely used in production workshops, warehouses and freight yards. Crane working level is from A3 to A5.

.WEBP)

| Technical Parameter |

| Lifting Capacity(T) |

0.5 |

2 |

3 |

5 |

10 |

| Span(m) |

1-18 |

1-18 |

1-18 |

1-18 |

1-18 |

| Crane travel Mechanism |

travel speed(m/min) |

20/30 |

20/30 |

20/30 |

20/30 |

20/30 |

| motor |

power(kw) |

0.4*2 |

0.4*2 |

0.4*2 |

0.4*2 |

0.8*2 |

| rotation speed(n/min) |

1380 |

1380 |

1380 |

1380 |

1380 |

| Electric Hoist |

Electric hoist |

double speed |

double speed |

double speed |

single/double speed |

single/double speed |

| Lifting speed(m/min) |

8/0.8 |

8/0.8 |

8/0.8 |

8/0.8 |

3.5 |

| Cross speed(m/min) |

20/30 |

20/30 |

20/30 |

20/30 |

20 |

| Motor |

cone squirrel-cage model |

cone squirrel-cage model |

cone squirrel-cage model |

cone squirrel-cage model |

cone squirrel-cage model |

| working class |

A3 A4 A5 |

A3 A4 A5 |

A3 A4 A5 |

A3 A4 A5 |

A3 A4 A5 |

| Power voltage |

380V-690V 3 phase 50 Hz |

380V-690V 3 phase 50 Hz |

380V-690V 3 phase 50 Hz |

380V-690V 3 phase 50 Hz |

380V-690V 3 phase 50 Hz |

| wheel diameter(mm) |

130 |

130 |

130 |

150 |

| 工Rail |

120a-145c |

I 32a-I 45C |

I 32a-I 45C |

I 40b-I 63C |

2.3 Hook Crane

2.3.1 Headroom Electric Overhead Traveling Hook Crane

Headroom electric overhead traveling hook crane is a widely used lifting equipment, mainly composed of box weld beam, hoisting trolley, travelling mechanism, and electrical control system, load handing device is hook. There are rails laid on the main beam for hoisting trolley to move horizontally along the direction of the main beam. Main beam and end beam are weld in box form, there are joints, bolts or pin shafts arranged in the middle of the end beam for dismantling and transportation of the bridge. There are three operating modes available: cable pendant on the ground, wireless remote control, and driver's cab.

.WEBP)

2.3.2 Traditional Overhead Traveling Hook Crane

Overhead traveling hook crane is a widely used lifting machinery, mainly composed of box weld bridge, lifting trolley, crane traveling mechanism, and electrical control system. The retrieval device is a hook. There are rails laid on the main girder for the lifting trolley to move horizontally along the direction of the main girder.

The main girder is welded to the box weld end girder, and there are joints arranged in the middle of the end girder, which are connected by bolts or pin shafts for the disassembly and transportation of the bridge.

| Technical Parameter |

| Lifting capacity |

t |

5 |

10 |

20/5 |

50/10 |

75/20 |

100/20 |

200/50 |

450/80 |

| span |

m |

31.5 |

31.5 |

31.5 |

31.5 |

31.5 |

31 |

31 |

20.8 |

| Max lifting height |

main hook |

m |

16 |

16 |

16 |

12 |

20 |

22 |

32 |

25 |

| auxiliary hook |

|

|

14 |

16 |

22 |

22 |

32 |

33 |

| speed |

lifting |

main |

A5 |

m/min |

11.3 |

8.5 |

7.2 |

5.9 |

6.1 |

3.9 |

2.8 |

0.895 |

| A6 |

15.6 |

10.4 |

9.8 |

7.8 |

6.1 |

4.9 |

3.1 |

| Auxiliary |

|

|

14.6 |

15.5 |

7.2 |

7.2 |

9.8 |

4.84 |

| Cross travel |

37.2 |

43.8 |

44.6 |

44.6 |

38.5 |

33.86 |

28 |

5.1 |

| long travel |

A5 |

91.8 |

84.7 |

87.6 |

74.6 |

65 |

65.7 |

58 |

20 |

| A6 |

93.7 |

86.5 |

89 |

76.6 |

66.2 |

65.7 |

43 |

| Weight |

trolley |

A5 |

Kg |

2500 |

3400 |

6856 |

15425 |

29150 |

35016 |

66500 |

119000 |

| A6 |

2550 |

3500 |

7180 |

16400 |

29154 |

35416 |

74000 |

| total weight |

A5 |

Kg |

31405 |

34405 |

41497 |

64880 |

95548 |

110530 |

183000 |

231700 |

| A6 |

31596 |

34669 |

44225 |

67242 |

97923 |

116110 |

207000 |

| Max wheel pressure |

A5 |

kn |

125 |

160 |

231 |

450 |

341 |

412 |

390 |

780 |

| A6 |

126 |

162 |

239 |

457 |

355 |

428 |

400 |

| Recommended rail |

43kg/m |

43kg/m |

QU80 |

QU100 |

QU100 |

QU100 |

QU120 |

| Power source |

380-600V 50HZ 3 Phase |

2.4 Electric Hoist Overhead Traveling Crane

2.4.1 Headroom Electric Hoist Overhead Traveling Crane

Headroom electric hoist overhead traveling crane is a new type of crane introduced and digested advanced foreign technology, guided by modular design theory and modern computer technology. It adopts optimized design and reliable design methods, and is completed with imported configurations, new materials, and new processes, which is lightweight, universal, energy-saving, environment friendly, maintenance free, and high-tech.

2.4.2 Traditional Electric Hoist Overhead Traveling Crane

Traditional electric hoist overhead traveling cane consists of box weld bridge, long traveling mechanism, cross travelling mechanism and electrical system, it adopts stationary type electric hoist mounted on the hoist trolley as a lifting mechanism. The cross traveling mechanism adopts LD mode transmission, long traveling mechanism adopts LD and QD two types transmission.

The structure is simple and lightweight, with the characteristics of small overall height and light self weight, suitable for workplaces such as factories, mines, workshops, and warehouses within the range of medium and small lifting weights. There are three operating modes: cable pendant on the group, wireless remote control, and driver's cab. There are two types of cabins: open and closed.

| Technical Parameter |

| Lifting weight |

T |

3 |

5 |

10 |

16 |

20 |

| Operation mode |

Pedant/ cabin |

| speed |

hoisting |

m/min |

0.8/8 |

0.8/8 |

0.7/7 |

0.35/3.5 |

0.6/6 |

| cross travel |

20 |

20 |

20 |

20 |

20 |

| long travel |

ground |

20/30 |

20/30 |

20/30 |

20/30 |

20 |

| cabin |

20/30 |

20/30 |

20/30 |

20/30 |

20 |

| Motor |

lifting |

Type/kw |

ZD1 32-4/4.5 |

ZD1 41-4/7.5 |

ZD1 51-4/13 |

ZD1 51-4/13 |

ZD1 52-4 |

| cross travel |

YSE80 -0.4*2 |

YSE80-0.8*2 |

YSE80-0.8*2 |

YSE90L-1.5*2 |

YSE90L-1.5*2 |

| long travel |

ground |

YSEP90L-1.5*2 |

YSE90L-1.5*2 |

YSE90L-1.5*2 |

YSEP90L-1.5*4 |

YSEP90L-1.5*4 |

| cabin |

ZDR100-1.5*2 |

ZDRI00-1.5*2 |

ZDRI00-1.5*2 |

ZDR100-1.5*4 |

ZDR100-1.5*4 |

| Lifting height |

m |

9 12 |

12 18 |

9 12 |

9 12 |

9 12 |

| span |

m |

31.5 |

31.5 |

31.5 |

31.5 |

31.5 |

| Working class |

A3-A4 |

| Recommended rail |

kg/m |

24 |

38 |

38 |

38 |

38 |

| Max wheel pressure |

kn |

87 |

95 |

132 |

178 |

218 |

| Dead weight |

pendant |

T |

19.1 |

20.7 |

23 |

26.7 |

29.7 |

| cabin |

19.9 |

21.5 |

23.8 |

27.5 |

30.5 |

2.5 Side Hung Trolley Type Single Girder Traveling Crane

This crane consists of box weld main girder, end girder, hoisting trolley and traveling mechanism. The electric hoist is installed on the angle shaped trolley as the lifting mechanism, and the angle shaped trolley is arranged on one side of the main girder for traveling. The trolley is equipped with upper and lower flat wheels, which are arranged at three points with the vertical traveling wheel.

The position of the electric hoist has been raised from the traditional bottom of the main girder to the upper side of the main girder, effectively improving the lifting height. The hoisting trolley is driven by conical motor and open gear transmission. The main girder is box weld structure. Horizontal wheels are installed above and below the deviation rail, which is safe and reliable, and can prevent rail biting. Crane bridge travels in a separate drive, conical motor brakes and open gear transmit.

.WEBP)

2.6 Magnet Overhead Traveling Crane

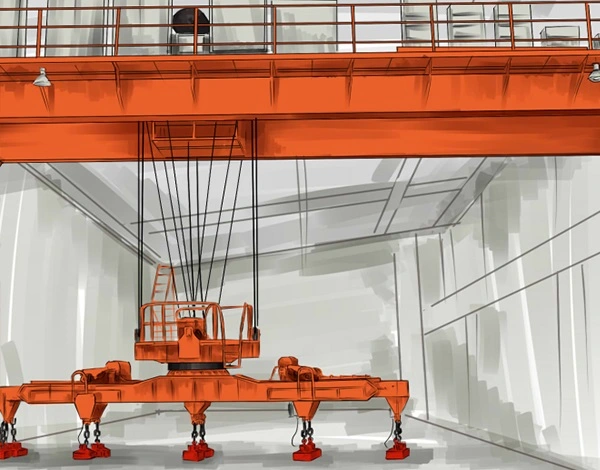

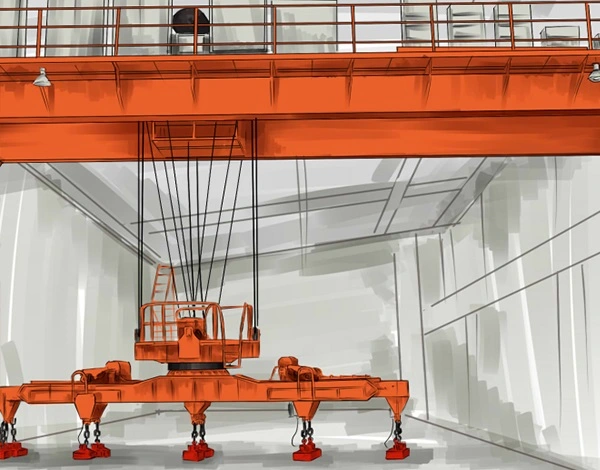

2.6.1 Overhead Traveling Crane with Slewing-Hanging beam

This crane is used for transporting black metals such as long slabs and bars, etc. Slewing is achieved in two forms: one form is the hanging beam slewing, which means the hanging beam is a double-layer structure. The upper hanging beam is wrapped with a pulley group and steel wire rope, and the lower hanging beam is equipped with multiple electromagnet or clamps, which can rotate at a certain angle with the driving mechanism.

Another form is slewing trolley, which means the trolley is a double-layer structure, with a lifting mechanism arranged on the upper trolley and a traveling mechanism on the lower trolley. A circular rail is laid on lower trolley, and the upper trolley can slew along the circular rail.

| Hanging Beam Slewing Crane Technical Parameter |

| Clean lifting capacity |

T |

15 |

25 |

30 |

| working class |

|

A6 |

| span |

m |

34.3 |

46.3 |

53.3 |

| Lifting height |

m |

5.5 |

5 |

5 |

| speed |

lifting |

m/min |

12.2 |

11.8 |

12 |

| traveling |

cross travel |

38 . 7 |

38 |

40.8 |

| long travel |

82. 5 |

82.5 |

82.5 |

| hang beam |

Rotation |

1 |

1 |

1 |

| telescoping |

5/10 |

5/10 |

5/10 |

| Max wheel pressure |

Kn |

220 |

325 |

410 |

| Recommended rail |

QU100 |

| power source |

380-600V 3Phase 50hz |

.WEBP)

| Slewing Trolley Crane Technical Parameter |

| Lifting capacity |

T |

5+5 |

10+10 |

16+16 |

25+25 |

| working class |

|

A6 |

A7 |

A6 |

A6 |

| span |

m |

28.5 |

25 |

34 |

25 |

33 |

25 |

| Lifting height |

m |

12 |

16 |

16 |

10 |

16 |

10 |

| speed |

lifting |

m/min |

12.4 |

12.6 |

12.6 |

14.8 |

16 |

15.4 |

| traveling |

cross travel |

44.2 |

42.2 |

42.4 |

39 |

48 |

40 |

| long travel |

102 |

85.2 |

85.2 |

106 |

101 |

107 |

| hang beam |

Rotation |

r/min |

1.5 |

1.36 |

1.36 |

1.36 |

1.85 |

1.4 |

| Max wheel pressure |

Kn |

65 |

190 |

210 |

255 |

260 |

335 |

| Total power |

kw |

50.2 |

114.8 |

128.8 |

151.3 |

196 |

243.5 |

| Recommended rail |

43kg/m |

QU80 |

QU100 |

| power source |

380-600V 3Phase 50hz |

2.6.2 Magnet crane with hanging beam

This crane uses hanging beams to lift long steel billets, plates, bars, coils, and other items, equipped with magnetic chuck or clamps or special group hooks for lifting. It mainly consists of a box weld bridge, a lifting trolley, crane traveling mechanism, driver's cab and electrical control system, equipped with a power off magnetic-function keep system.

The lifting mechanism often adopts a single motor, double reducer, and double drum layout, in the form of double lifting points. The arrangement of hanging beams can be divided into two types: perpendicular to the main beam or parallel to the main beam, the remaining forms are the same as hook cranes.

| Technical Parameter |

| Lifting capacity |

t |

5+5 |

7.5+7.5 |

10+10 |

16+16 |

20+20 |

| span |

m |

31.5 |

31.5 |

31.5 |

31.5 |

31.5 |

| Max lifting height |

m |

16 |

16 |

12 |

16 |

12 |

| working class |

A6 |

|

| speed |

lifting |

main |

A6 |

m/min |

13.2 |

13 |

13 |

9.5 |

11.8 |

| Auxiliary |

A7 |

15.7 |

12.5 |

13.5 |

13.6 |

15.22 |

| Cross travel |

43.8 |

44.8 |

45 |

43 |

38.9 |

| long travel |

A6 |

112.5 |

101.4 |

102..5 |

86.8 |

87.3 |

| A7 |

114.9 |

100.6 |

119.6 |

119 |

119.2 |

| Weight |

trolley |

A6 |

Kg |

6900 |

8500 |

8900 |

13200 |

17500 |

|

A7 |

7200 |

8900 |

9300 |

14100 |

18100 |

|

total weight |

A6 |

Kg |

41200 |

47300 |

49300 |

69500 |

72100 |

|

A7 |

43200 |

49800 |

51200 |

73500 |

78700 |

| Max wheel pressure |

A6 |

kn |

183 |

241 |

269 |

381 |

473 |

| A7 |

189 |

247 |

273 |

392 |

489 |

| Recommended rail |

43kg/m |

| Power source |

380-600V 50HZ 3 Phase |

2.6.3 Electromagnet Overhead Traveling Crane

The basic structure of an electromagnet overhead traveling crane is the same as that of a hook overhead crane, except that a DC lifting electromagnetic chuck is hung on the hook to lift magnetic black metal and its products. The AC power is converted into DC power through a thyristor DC box installed in the driver's cab, and then the DC power is sent to the electromagnetic chuck through a dedicated cable reel installed on the trolley.

| Technical Parameter |

| Lifting capacity |

t |

5 |

10 |

20/5 main hook with electromagnet |

32/5 auxiliary hook with electromagnet |

| span |

m |

31.5 |

31.5 |

31.5 |

31.5 |

| Max lifting height |

main hook |

m |

16 |

16 |

12 |

16 |

| auxiliary hook |

|

|

18 |

18 |

| working class |

A6 |

| speed |

lifting |

main |

electromagnet |

m/min |

15.6 |

13 |

13 |

9.5 |

| Auxiliary |

14.6 |

15.5 |

| Cross travel |

39.5 |

43.8 |

44.6 |

43.4 |

| long travel |

|

93.7 |

86.4 |

89 |

75.3 |

| Weight |

trolley |

|

Kg |

2496 |

4662 |

6822 |

12210 |

| total weight |

|

Kg |

32840 |

39200 |

42820 |

57140 |

| Max wheel pressure |

|

kn |

134 |

173 |

214 |

341 |

| Recommended rail |

43kg/m |

| Power source |

380-600V 50HZ 3 Phase |

| electromagnet |

Model |

MW1-16 |

MW1-16 |

MW5-180L |

MW5-210L |

| Attracting weight |

kg |

3330 |

8330 |

14500 |

21000 |

| Dead weight |

1670 |

1670 |

4230 |

7000 |

| Diameter |

mm |

1180 |

1180 |

1800 |

21000 |

2.7 Double Trolley Overhead Traveling Crane

The difference between a double girder trolley overhead traveling crane and a hook overhead traveling crane lies in the installation of two hoisting trolley on the main girder, which can be lifted or operated independently; When it is necessary to lift long items, synchronous lifting and running can be achieved through the conversion switch on the control console.

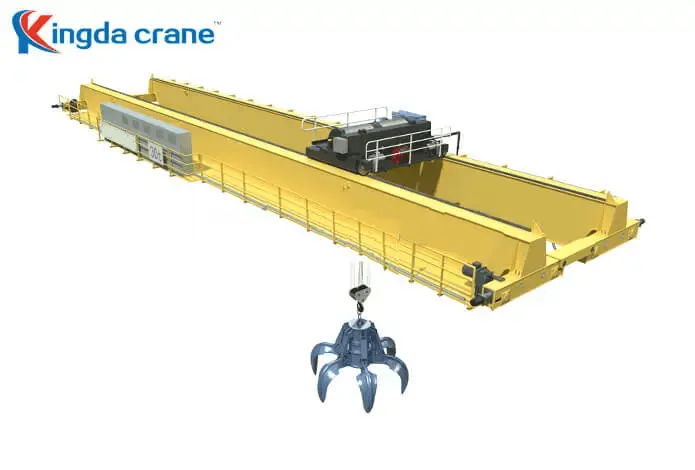

2.8 Grab Overhead Traveling Crane

Grab overhead traveling crane consists of box-weld bridge, grab trolley, long traveling mechanism, driver cabin and electric control system. The retrieval device is grab. Grab trolley is equipped with lifting and closing mechanism, and the grab is separately winded in the lifting and open-close drum by 4 wire rope. The open-close mechanism drives the grab to close and grab material; When the grab outlet is closed, the lifting mechanism is started immediately, make 4 wire rope having same stress and carrying out lifting action. Only open-close mechanism is under working, along gran outlet is open, the material is poured out. Except the lifting mechanism is different, the others is the same compared with hook overhead traveling crane.

| Technical Parameter |

| Lifting capacity |

t |

5 |

10 |

16 |

20 |

| span |

m |

31.5 |

31.5 |

31.5 |

31.5 |

| working class |

A6 |

| Lifting height |

m |

20 |

18 |

22 |

26 |

| speed |

lifting |

m/min |

40.1 |

40.7 |

41.8 |

48.6 |

| Cross travel |

44.6 |

45.6 |

43.2 |

43.2 |

| long travel |

86.4 |

89 |

87.3 |

87.3 |

| Weight |

trolley |

Kg |

5200 |

8200 |

14800 |

19300 |

| total weight |

indoor |

41300 |

50400 |

67900 |

75600 |

| out door |

42100 |

51200 |

69000 |

76800 |

| Max wheel pressure |

indoor |

kn |

144 |

196 |

263 |

312 |

| out door |

148 |

201 |

268 |

316 |

| Grab |

Model |

113 |

110 |

106 |

102 |

130 |

148 |

144 |

| Type |

light |

medium |

heavy |

super heavy |

super heavy |

heavy |

super heavy |

| Volume(M3) |

2.5 |

1.5 |

1 |

0.75 |

2.5 |

4 |

3 |

| Density t/m3 |

1-1.7 |

1.7-2.5 |

2.5-3.3 |

2.5-3.3 |

|

|

| Dead weight(kg) |

2632 |

2615 |

2568 |

2546 |

8305 |

10123 |

9927 |

| Recommended rail |

43kg/m |

QU70 |

| Power source |

380-600V 50HZ 3 Phase |

3. conclusion

Overhead traveling crane is an important tool and equipment in modern industrial production and lifting transportation to achieve mechanization and automation of the production process. Therefore, overhead traveling cranes are widely used in indoor and outdoor industrial and mining enterprises, steel and chemical industries, railway transportation, ports and terminals, as well as logistics turnover departments and places.

Kingda Overhead Traveling Crane