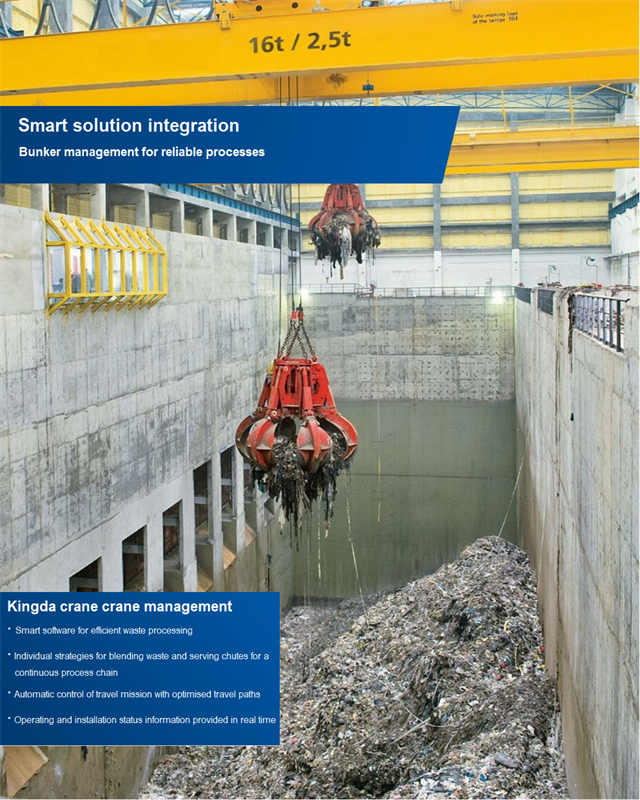

1. Waste Handling Grab Crane General Introduction

Kingda waste handling grab crane is a tailored lifting equipment for refuse incineration power plant, Waste to energy power plant or biomass co-generation plant. The crane uses grab to picking up- transporting-feeding-weighting waste and sludge, and depositing into incineration furnace. Waste handling grab crane can be operated in automatic and intelligent mode, improve waste handling efficiency and safety.

Kingda waste handling grab crane is mainly divided in to overhead type waste handling grab crane and gantry type waste handling grab crane. Overhead type crane is overhead above refuse pit, the crane bridge travel along two side’s rail, this type crane can greatly use all available space under crane to deal with materials, with no limitation from ground equipment. Gantry type waste handling grab crane is organized by four legs and one or two main girders, its main girder can be cantilever or not, the hoist trolley moves inside the main girder. Gantry type grab crane leg’s height can be adjusted by working environment, there are full gantry grab crane, semi-gantry grab crane and cantilever gantry grab waste handling crane.

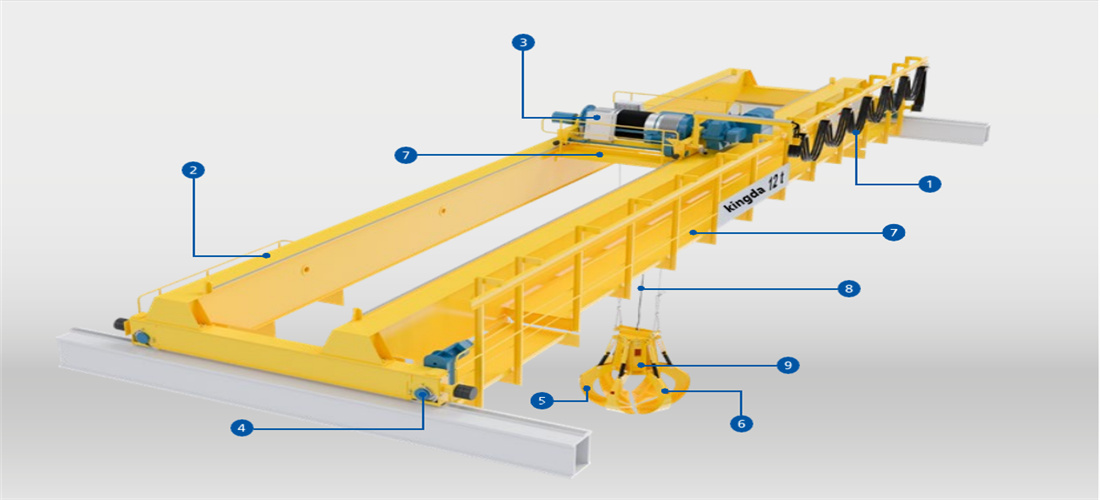

Waste handling grab crane is organized by lifting hoist/trolley, bridge travelling mechanism and bridge steel structure. Lifting hoist/trolley is organized by lifting mechanism, trolley travelling mechanism and trolley steel frame. Lifting mechanism includes motor, brake, reducer, drum and pulley block, it can control grab’s lifting-lowering and opening-closing; Hoist/trolley includes motor, reducer and driving wheel, it can control hoist trolley’s horizontal motion along the main girder; hoist/trolley steel frame bears grab and lifting material’s weight, to connect lifting mechanism and hoist/trolley cross travelling mechanism. Bridge long travelling mechanism includes motor, brake, reducer and driving wheel, it can control the whole crane bridge move on the rail. Bridge steel structure is organized by main girder, end girder and legs, etc., it bears all the weight from hoist/trolley and lifting materials, and transfer the pressure to rail or ground foundation.

Kingda waste handling grab crane’s lifting capacity is demonstrated by rated lifting capacity and working class/level. Rate lifting capacity’s is grab crane’s Max. Safe lifting weight under normal operating condition. Working class/level means crane’s load status class/level in a pointed cycle. Waste handling grab crane working class/level can be A5-A6-A7-A8, or medium duty and heavy duty. Waste handling grab crane’s rated lifting capacity is different depending on different crane type and structure, in 5~40t.

Kingda waste handling grab crane main application scene are waste to energy power plant/refuse incineration power plant or co-generation plan, landfills and refuse transfer station. energy power plant/refuse incineration power plant is a incineration- power generation facility that uses house and industrial refuse or sludge to be a fuel and heat energy produced by incineration drives steam turbine to get electric power finally. In those application scenes, waste handling grab crane can fulfill waste’s picking up and feeding in rapid-accurate and safe, with high performance and high quality.

Wasting handling grab crane’s price is different by different type, structure, lifting capacity and configuration, the price rang:100,000RMB-300,000,000RMB. Crane’s main performance are reflected on operation, stability, reliability and durability. Performance means whether the crane can be operated and controlled easily, whether the crane can satisfy different working requirement and working environment; stability means the crane whether can insure stable and precise running continuously, whether the crane can withstand interference of wind power and seismic force; Reliability means whether the crane can work under normal and good condition for a long time, whether it is easy be damaged or in breakdown; Durability means whether the crane can withstand severe operating condition, whether the crane can extend service life and reduce maintaining cost.

Kingda wasting handling grab crane’s main advantages:

1) Can fulfill to deal with waste/refuse’s transporting and feeding in automatic,intelligent; Reduce personal cost and safe risk;

2) Can depending on different application scene and refuse/waste condition, to choice suitable grab and crane technical parameter, improve transport efficient and space efficient;

3) Can depending on different operating requirement and condition, choose suitable lifting capacity and configuration, improve feeding efficient and quality;

4) It is a lifting equipment with many kinds mode, structure, lifting capacity and configuration, not only can realize transporting-feeding in automatic, smart, high efficient and safety, but also can boost waste/refuse’s processing efficiency and quality, save human cost and energy consumption, is a environment protection, economic facility.

2. Waste Handling Grab Crane Project introduction

2.1 project content

| Project name: |

House Refuse Incineration Power Plant Project in Ninghua Country Town.China |

| Project owner: |

Sanming Jinyuan Environment and New Energy Co.,ltd. |

| Project Scale: |

refuse/waste handling capacity 500t/day, the project plan to set

up refuse/waste incineration power plant with 400t/day,

equipped with 1 set 10MW Steam turbine generator, the whole

installation can achieve efficient working time≥8000 hours. |

| Incineration quantity: |

1 set |

| Incineration furnace handling capacity: |

400t/day |

| Steam turbine rated power: |

10MW/set |

| Steam turbine quantity: |

1 set |

| Rated running time |

≥8000 hours |

| Service life |

≥ 30 years |

2.2 waste/refuse resource

Waste /refuse mainly from Qinghua and Qingliu county town’s house refuse, and sewage sludge from Qinghua (moisture content:60%), and general industrial refuse.

2.3 standard and specification

Kingda wasting handling grab crane’s design, manufacturing, installation, commission, test and final delivery should follow China standard and China Law:

- applying standard should not lower than China standard, otherwise, should follow China standard;

- all relating affairs:environment, environment protection, fire protection should follow China Law;

- Equipment material should follow China law.

3. Crane technical data sheet

| Item |

|

Specification |

| quantity |

: |

2 set |

| Layout |

: |

single layer rail |

| crane mode |

: |

semi-automated double girder hydraulic grab crane |

| service life |

: |

≥30 years |

| lifting capacity |

: |

≥11t |

| overload capacity |

: |

≥20% |

| Min.running time |

: |

≥8000 hours/year |

| total inciration capacity |

: |

440t/day |

| working class |

: |

A8 |

| wire rope material |

: |

galvanizing |

| lifting speed |

: |

≤45m/min |

| lowering speed |

: |

≤60m/min |

| cross travel speed |

: |

≤60m/min |

| long travel speed |

: |

≤65m/min |

| electric protection class |

: |

IP55 |

| insulation class |

: |

F |

| grab volume |

: |

6.3M3 |

| control mode |

: |

manual + semi-automated |

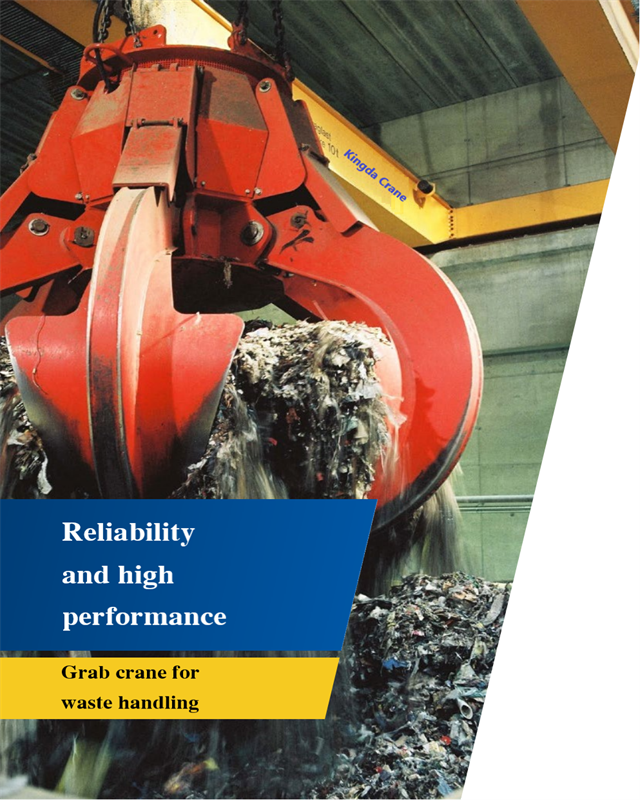

4. Waste Handling Grab Crane Technical advantages:

High-level efficiency

Kingda waste handling grab crane

1. Reliable supply: rugged cable system for reliable transfer of power and process data – also under extremely harsh conditions

2. Optimized weight: compact crane girder and crab design

3. Efficient processes: integrated weighing system with data transfer

4. Precisely guided: individually adjustable wheels with hardened surfaces

5. Firm grip: hydraulic multi-jaw grabs with high capacity

6. Reliable operation: central system to lubricate the whole crane mechanism

7. Fast and reliable positioning: high speeds thanks to load-sway reduction and 2/2 rope reeving

8. 1High efficiency: integrated sensors for 24/7 automatic operation Easy to service: maintenance platforms for direct access to the crane and components

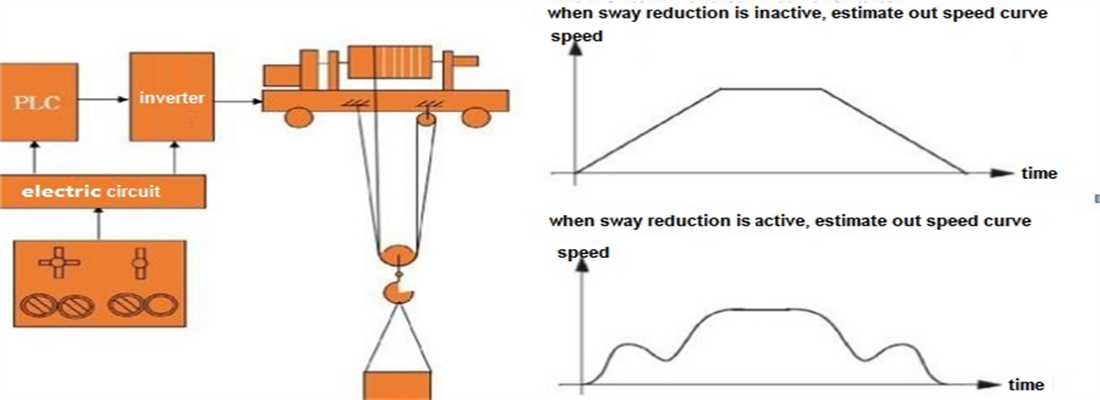

4.1 load sway reduction technical solution

4.1.1 load sway control system

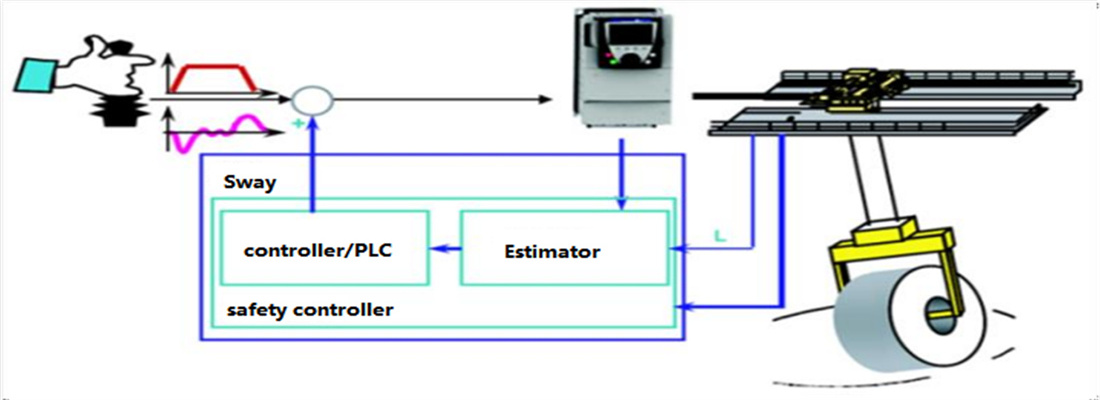

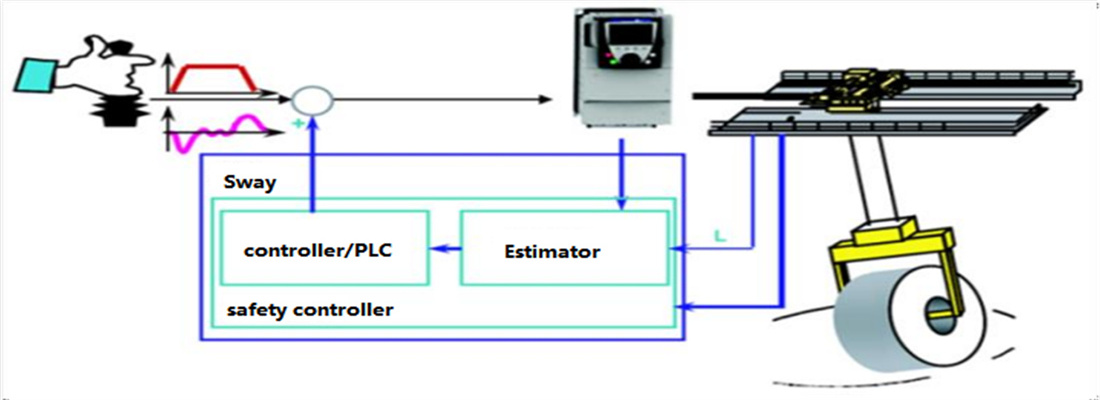

Load sways reduction is continuously realized by modifying speed order single which send to the inverter, there will be no sway or with Min. sway when the lifting object arrives set up speed or with no moving. Due to no need to wait the lifting object stopping sway, and can fulfill precise positioning, so load sway reduction system can significantly save operation time.

PLC load sway control system, through adaptive model, bases on the following factors to estimate lifting object’s sway:

- 1. Frequency’s inner single

- 2. Rope length and loading height of gravity center

4.1.2 Waste handling grab crane safety control

- 1) Used in speed reducing and stopping area

- 2) Used to activate or deactivate load sways control function

- 3)Get rope length and loading gravity height, rope length can be got by lifting mechanism: encoder

- 4) For inverter controlled lifting , encoders are fitted on lifting motor, encoder single are connected to inverter’s encoder card;

- 5) For non-frequency inverter controlled lifting, encoder can be installed on the drum’s center shaft, the single can be connected to PLC. Using encode to calculate crane’s position is a high precision method, and also can achieve a good load sway reduction in any height;

4.1.3 positioning system sets up grab sway reduction

When conventional waste handling grab crane is under working condition, the grab will sway along with bridge’s long travel or trolley’s cross travel, in order to avoid colliding other objects, and avoid effecting crane’s depositing work in feeding pit, the waste handling grab crane should be fitted with load sway control system.

Electrical load sway reduction has no influence to mechanical structure, sway reduction rate can up to above 80%, can fulfill swing amplitude <30mm in 2 swaying cycles, adjusting principle as following:

4.1.4 Position detection

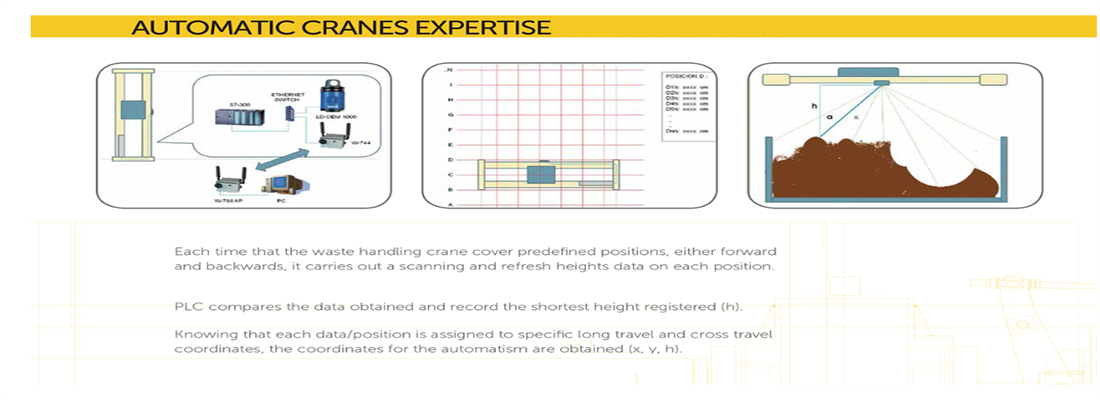

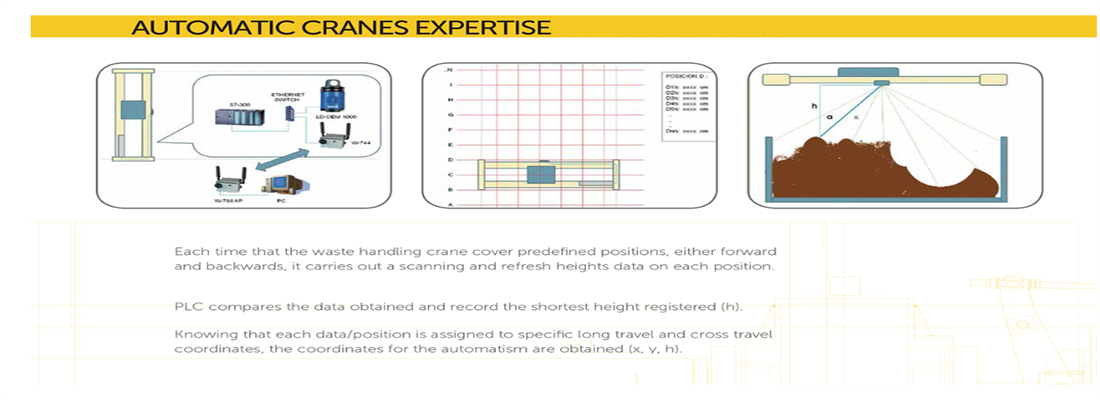

Kingda waste handling grab crane's position detection system has no high requirement to position detection, discharge port’s width is greatly bigger than grab’s diameter, so we apply absolute value encoder proposal. In order to avoid system position’s precision effected by wheel sliding, absolute value encoders are installed in long and cross travel’s following wheel, and set register mark above every discharge port( 1 mark/ 10m long travel rail), when the travelling mechanism pass by register mark, system will automatically compares calculated position and detecting position, eliminating accumulative error.

Register mark applies comparison of fixed position and calculated position, if deviation is less than a value, we think it is reasonable deviation; Depending on register mark’s position information and resetting encoder’s calculated value, if deviation is big than a value, the waste handling grab crane smart system will starts diagnosis mode, reset position information and automatically move to next register mark, if the deviation is still big than a value, we think that the encode is in breakdown, smart system will alarm and automatically avoid this breakdown mark, the other system starts to work.

4.2 Anti-side pull technical solution

Kingda waste handling grab crane's hardware configuration: apply laser positioning technology, drill hole in lifting trolley and install laser launcher in the hole. Laser direction is vertical to the ground, and install detecting point on the hook or spreader. When there is side pull or side lifting, laser detecting point will be deviation from laser launcher, then launcher stops sending lifting single to waste handling grab crane.

4.3 Collision protection technical solution

To avoid two cranes won’t collide when they are in automatic operation, the bridge long travel mechanism should be fitted with anti-collision protection function. Through ultrasound sensor (installed in the middle of two cranes) to detects in time the real distance from neighboring equipment; if the distance is smaller than pointed value, the bridge will stop moving forward. Also, the smart system can detect grab wire rope break and power cable break.

4.4 Positioning system technical solution

Automatic waste handling grab crane has a high requirement to positioning system, and has to give consideration to sway reduction, so the system applies S7 bus wire in time regulation, deceleration curve produce automatically position control mode; depending on crane’s current speed, the system can automatically calculate out decelerating and stopping distance, when the distance gets to limited value, PLC system will send sop curve to driver, frequency inverter carry out this order, positioning precision can be 20mm.

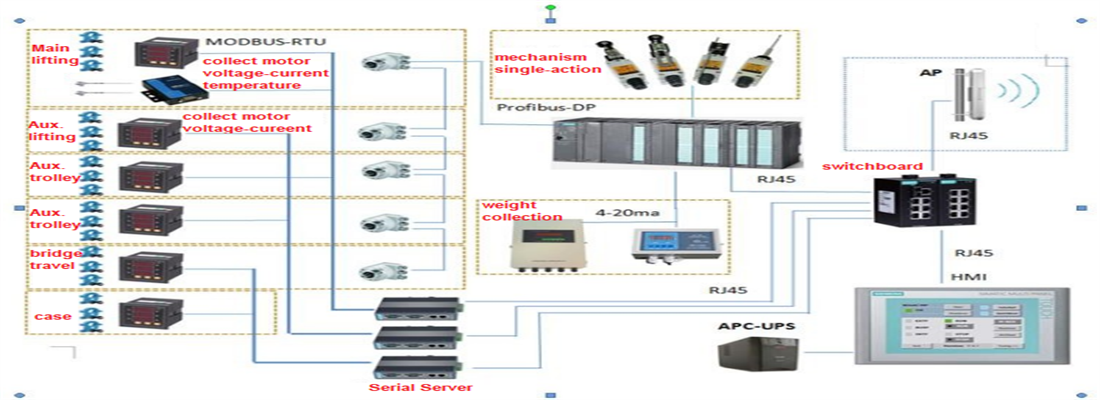

4.5 Management system and security monitoring system

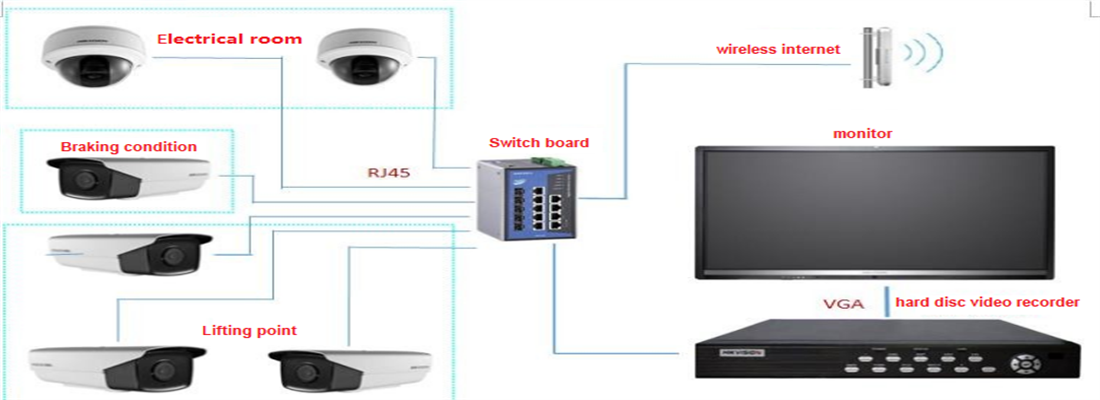

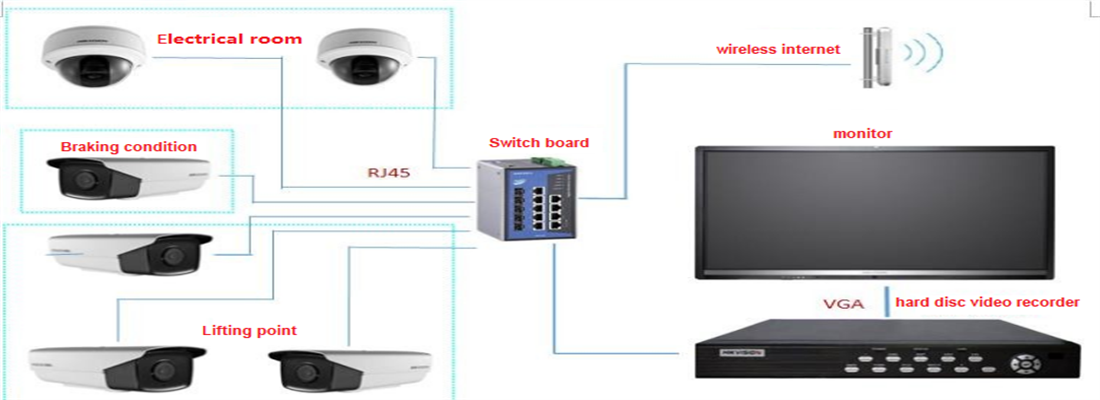

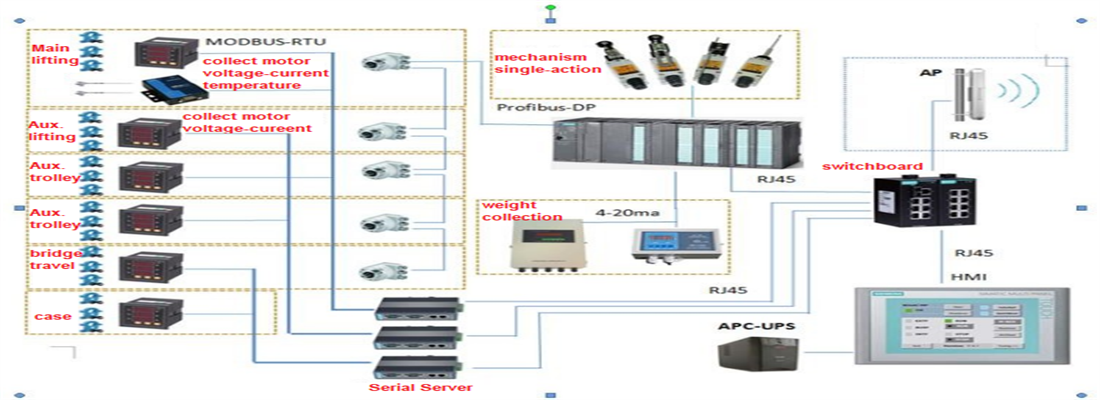

Waste handling grab crane security monitoring system organized by two systems: date monitoring system and video monitoring system, including signal transmission, collect, process, storage and display data.

4.5.1 Date monitoring system

4.5.2 Video monitoring system