| Lifting capacity(T) | 125/32 | 140/32 | 160/32 | 225/65 | 280/80 | 320/80 | |

| working class | A7 | A7 | A7 | A7 | A7 | A7 | |

| span (mm) | 19 | 19 | 27 | 27 | 22 | 24.5 | |

| Lifting height(m) | Main hook | 24 | 22 | 25 | 32 | 29 | 28 |

| Auxiliary hook | 26 | 24 | 26 | 34 | 29 | 32 | |

| Speed(m/min) | Main hook | 7.6 | 7.8 | 9.8 | 11 | 12 | 7.5 |

| Auxiliary hook | 9.7 | 9.7 | 12 | 11 | 10 | 10 | |

| Main Cross travel | 38 | 36 | 43.5 | 41 | 40 | 29 | |

| Auxiliary Cross travel | 39 | 37.5 | 43.5 | 39.5 | 40 | 39 | |

| Long travel | 76 | 73 | 84 | 84 | 80 | 58 | |

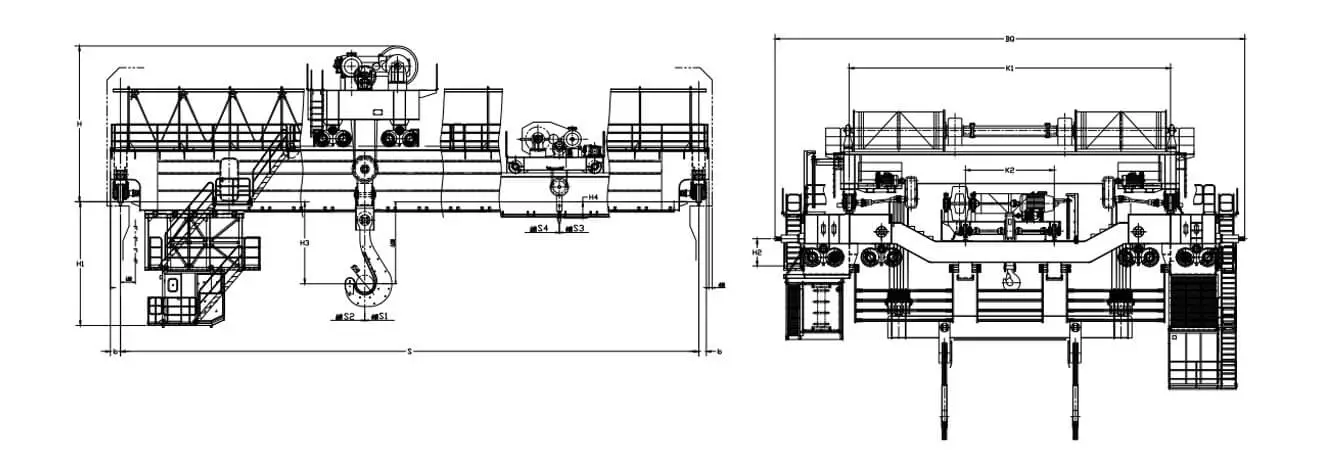

| Main dimensions(mm) | H | 5690 | 5880 | 6350 | 7000 | 7800 | 7800 |

| H1 | 5500 | 5600 | 2700 | 5990 | 4700 | 6500 | |

| H2 | 1350 | 1350 | 1250 | 1400 | 1350 | 1500 | |

| BQ | 15800 | 15800 | 16800 | 17300 | 18530 | 19500 | |

| B1 | 10120 | 10100 | 10800 | 10100 | 10500 | 12500 | |

| B2 | 2800 | 2500 | 3300 | 3300 | 3800 | 5000 | |

| Limit dimension(mm) | b | 410 | 450 | 550 | 450 | 550 | 550 |

| H3 | 4200 | 4350 | 6000 | 5800 | 6000 | 6000 | |

| H4 | 1300 | 1500 | 1100 | 1000 | 2000 | 1700 | |

| S1 | 2200 | 2300 | 2800 | 2500 | 3200 | 3300 | |

| S2 | 2000 | 2000 | 26650 | 3000 | 3500 | 3500 | |

| S3 | 1500 | 1500 | 1800 | 2200 | 2400 | 2600 | |

| S4 | 1500 | 1600 | 2200 | 1600 | 2800 | 3000 | |

| Max wheel pressure (Kn) | 505 | 535 | 485 | 420 | 735 | 750 | |

| Recommended rail | QU120 | ||||||

| power source | 380-600V 3 phase 50HZ | ||||||