| Clean lifting capacity | T | 15 | 25 | 30 | ||

| Working class | A6 | |||||

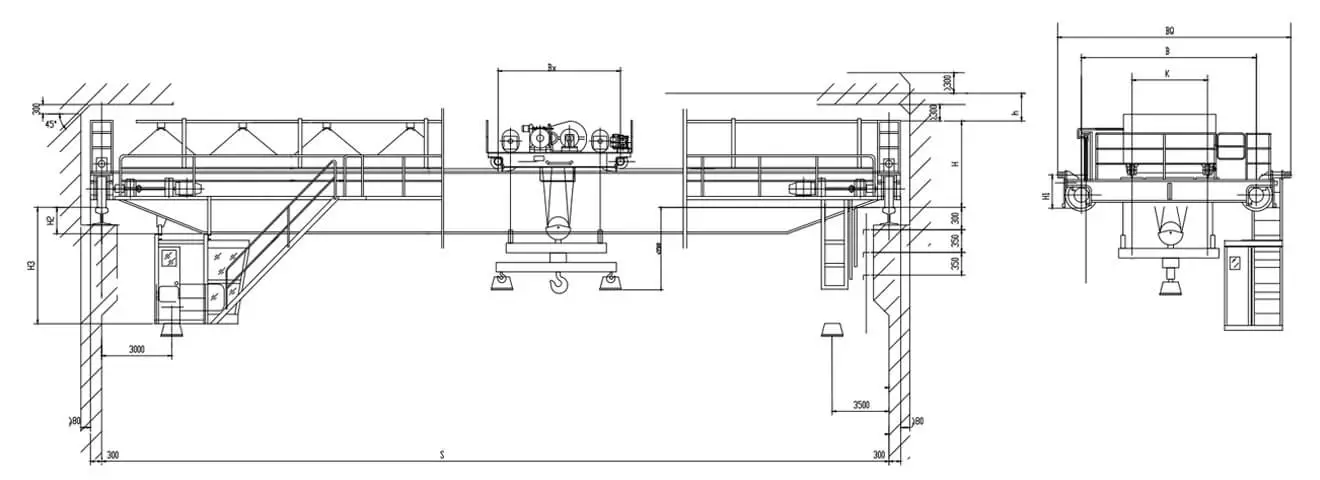

| Span | m | 34.3 | 46.3 | 53.3 | ||

| Lifting height | m | 5.5 | 5 | 5 | ||

| Speed | lifting | m/min | 12.2 | 11.8 | 12 | |

| traveling | cross travel | 38 . 7 | 38 | 40.8 | ||

| long travel | 82. 5 | 82.5 | 82.5 | |||

| hang beam | Rotation | 1 | 1 | 1 | ||

| telescoping | 5/10 | 5/10 | 5/10 | |||

| Max wheel pressure | Kn | 220 | 325 | 410 | ||

| Recommended rail | QU100 | |||||

| Power source | 380-600V 3Phase 50hz | |||||