| Lifting capacity | T | 5+5 | 10+10 | 16+16 | 25+25 | ||||

| Working class | A6 | A7 | A6 | A6 | |||||

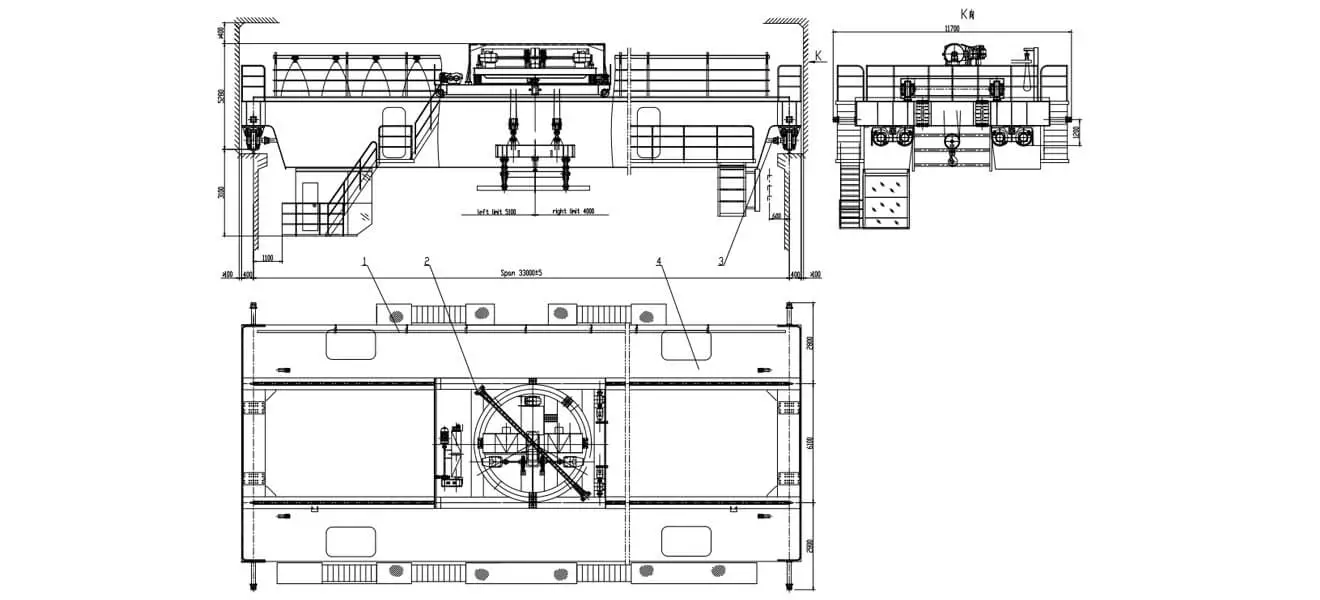

| Span | m | 28.5 | 25 | 34 | 25 | 33 | 25 | ||

| Lifting height | m | 12 | 16 | 16 | 10 | 16 | 10 | ||

| Speed | Lifting | m/min | 12.4 | 12.6 | 12.6 | 14.8 | 16 | 15.4 | |

| Traveling | Cross travel | 44.2 | 42.2 | 42.4 | 39 | 48 | 40 | ||

| Long travel | 102 | 85.2 | 85.2 | 106 | 101 | 107 | |||

| Hang beam | Rotation | r/min | 1.5 | 1.36 | 1.36 | 1.36 | 1.85 | 1.4 | |

| Max wheel pressure | Kn | 65 | 190 | 210 | 255 | 260 | 335 | ||

| Total power | kw | 50.2 | 114.8 | 128.8 | 151.3 | 196 | 243.5 | ||

| Recommended rail | 43kg/m | QU80 | QU100 | ||||||

| Power source | 380-600V 3Phase 50hz | ||||||||