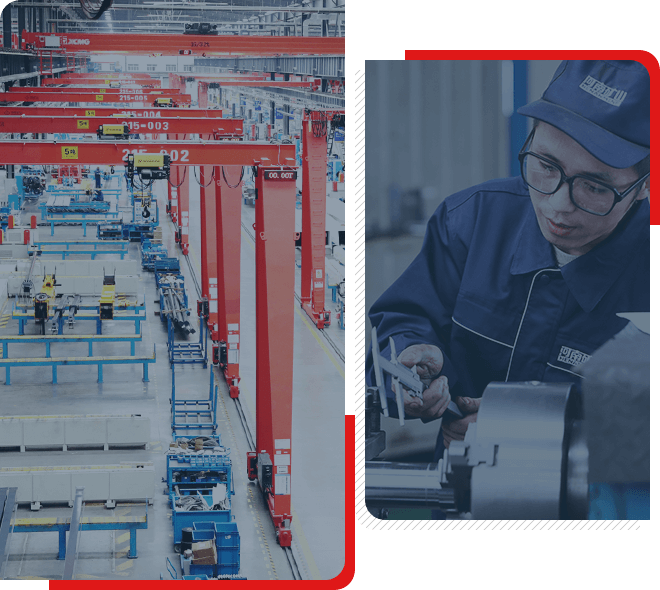

Secured material handling process

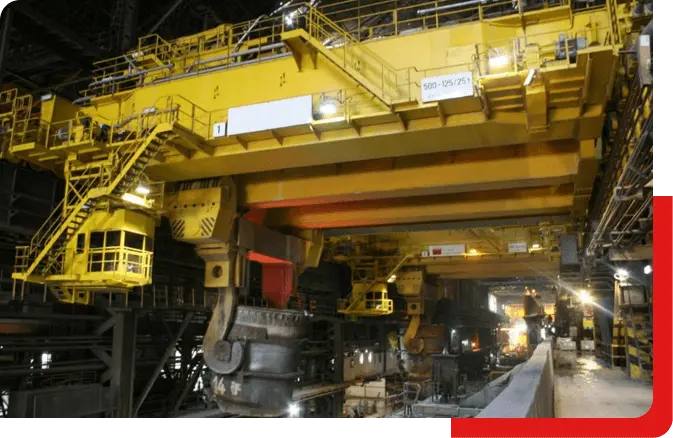

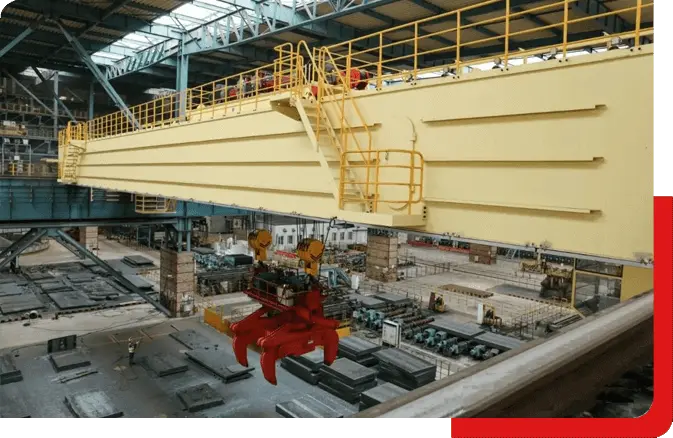

♦ Ladle crane services for metallurgy industry, there are double girder and four girder ladle cranes, working location is in blast furnace, converter and ladle furnace. Steel making needs protection from heat and dust, and the working class usually is heavy duty, working class up to A7 or A8.

♦ Casting crane is other name of ladle crane, we can also call them: molten metal handling double/four girders overhead travelling crane, or steel production EOT crane.

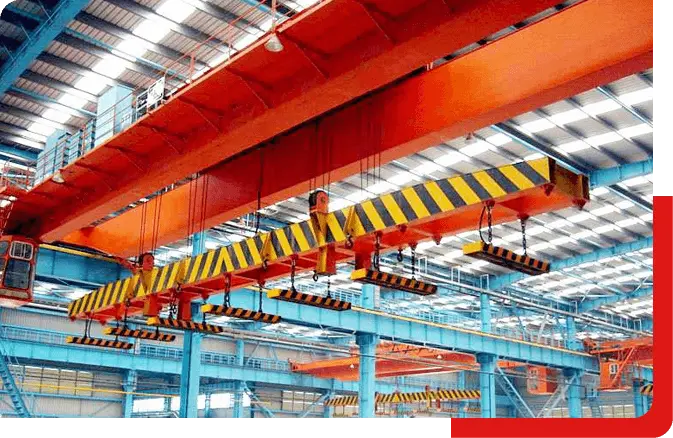

General double girder overhead crane, electric hoist and steel coils/steel roll crane, are used in plant's all working location, mainly for equipment installation and maintenance, for example sintering, continuous casting production line, blast furnace top, material yard and converter top.