Secured material handling process

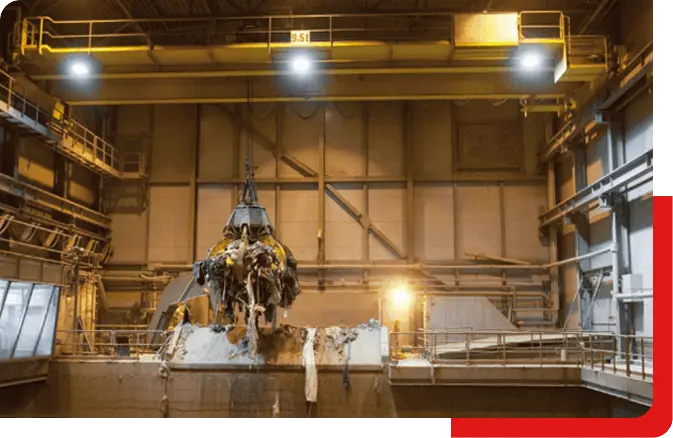

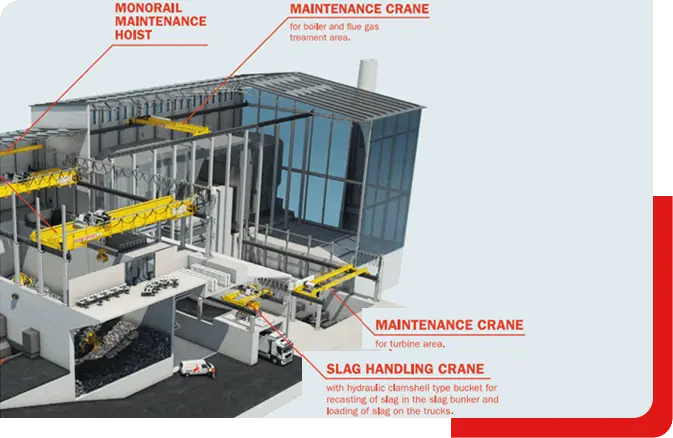

Crane play a crucial role in modern incineration plants, where tight environmental management guideline are applied. It is important that continuous materials handling system has maximum efficiency and uptime from the arrival of the waste, to separation, and to incineration. If the crane stop, the whole process is in danger. The kay factors, when specifying waste-to-energy cranes, are the total total burning capacity of the incinerators, the layout of the handling area, type of waste, and the time it takes to received and process the waste.

Typically, there are two waste handling cranes above the waste-pit, one of which is a backup. The primary crane undertakes the main operating functions whilst the other is being serviced.